|

|

|

1) Client Profitability

• Lowest part cost.

• Provide the best molds in terms of operational efficiency, requiring minimal operator supervision, providing the lowest scrap rates.

• Predictability

• Willing to make guarantees and back them up in writing.

• Deliver on time, fully functional molds ready to run in the client's facility.

2) Customer Intimacy

• Focused on developing long term relationships that are based on value.

• Attain an in depth understanding of our client's business that will allow us to develop an implicit understanding of their needs, reducing communication, errors and costs.

3) Easy to do Business With

• Quick turnaround time on inquiries.

• Fast answers to complex issues.

• Flexibility - we listen!

• More experience = less risk.

4) Front End Support

• Fully support your inquiries - will do more than just quote a mold!

• Spend time with clients at the inquiry stage to optimize mold and part designs, reducing the cost of the project.

• System configuration:

• Mold size.

• Hot runner selection.

• Machine size and option requirements.

• Product handling alternatives.

• Cycle estimates.

5) Value

• Full engineering support, including:

• Product design and development.

• Mold design optimization.

• 3D mold designs.

• Completely detailed mold components.

• Project management services, including:

• Project plan, including schedule.

• Formal kick off, design review and progress update meetings.

• Complete document control, including change notices.

• High quality molds:

• Fully hardened, completely interchangeable molding inserts.

• Pre-hardened, stainless steel mold bases.

• Fully interlocked core to cavity alignment.

• Completely optimized cooling and venting.

• Adjustment or tuning of critical sizes.

s to our clients that will save them time and money.

s to our clients that will save them time and money. Product Development

Speed to market is crucial to remaining competitive. By offering plastic product development services, Prosin Molds can effectively reduce this time. These services include:

Do you have a plastic product development or optimization requirement? Is your product development staff overloaded? If so, contact Prosin Molds today at sales@prosinmolds.com.

Mold Repair, Refurbishment and Maintenance.

In today's economy, getting the most out of a tooling investment is a priority. Prosin Molds offers mold repair and refurbishment services for not only the molds it has built, but for molds built by other mold makers. We will work with your production team to thoroughly plan the refurbishment process so the amount of down time is minimized. Once the mold is received, it will be completely dismantled and inspected to verify the corrective action. If the drawings and math data have gone missing, Prosin Molds has the capability to reverse engineer the mold to regenerate the information. Once complete, the molds are fully tested, delivered ready to run in your facility. Are you experiencing high scrap rates from your mold? Is your mold running as efficiently as it did when it was new? See what money can be saved by contacting Prosin Molds

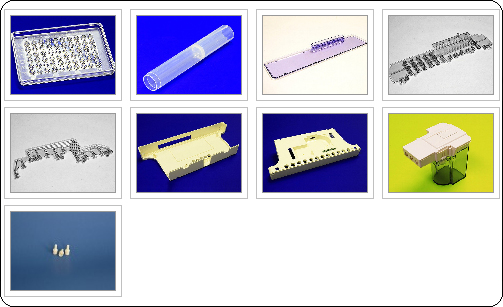

Prosin Molds offers a wide variety of injection mold products to prov ide the best injection molding solution for our cliental. Our expertise ranges from single face pilot tooling to 96 cavity molds.

ide the best injection molding solution for our cliental. Our expertise ranges from single face pilot tooling to 96 cavity molds.

Our products include:

Prototype and Pre-Production Pilot Molds

Single Face Molds

Stack Molds

Slide Action Molds

Bump off or Strip Molds

Unscrewing Molds

Collapsible Core Molds

Multi-Stage Ejection Molds

In Mold Product Handling

Hot Runner Technology

Prosin's expertise in hot runners allow us to integrate the hot runner of you r choice, provide recommendations or take full system responsibility. Hot runner companies we work with include Mold Masters and Husky Injection Molding Systems.

r choice, provide recommendations or take full system responsibility. Hot runner companies we work with include Mold Masters and Husky Injection Molding Systems.

Mold Testing

Prosin Molds delivers molds that are production ready. They are tested at the Negri-Bossi Canadian Technical Centre, located less than 4 kilometers from Prosin Molds. It is equipped with 80 to 400 ton machines and has the capability to web cast the molding parameters to our out of town customers as the machine is running. Each mold comes complete with test report and set up guide.

![]()

Products included in this segment are:

Prosin Molds Design and Manufacturing Capabilities - Providing 21st Century Solutions

Product Design and Engineering Our expert engineers work in 3D Solid Works, developing optimum solutions for any product. They provide personalized hands-on service through the entire development cycle of each item.

Mold Design and Engineering Mold design and engineering is a unique process for each and every product. Our expert engineers review and analyze even the smallest aspect of a product; assuring the production of only the highest quality, well-designed, and properly engineered molds. Design review meetings are conducted using 3D models. These meetings are often held remotely, using web-based conferencing software. This keeps our customers updated while reducing their travel costs.

Mold Manufacturing Prosin CNC programmers, mold makers, and machinists utilize our Manufacturing Process Plan, insuring information accuracy from engineering to production. Equipped with the latest, state-of-the-art machinery, our experts create reliable, high-quality production molds in a temperature controlled room.

Mold Modifications and Maintenance Whether product improvement or simple mold maintenance, challenges are easily met by the professionals at Prosin Molds. We engineer and execute required changes or improvements for any mold upon request, regardless of whether it was manufactured at Prosin or elsewhere.

Project Management Prosin subscribes to the Project Management Institutes best practices for managing projects. Our team is led by a Project Management Professional (PMP) to ensure cost-efficient products are delivered on time, without compromising quality or specifications.

Engineering Change All engineering changes whether internal or externally driven are fully documented to![]() ensure full traceability. Impact on project scope, time and/or cost is immediately communicated to our client.

ensure full traceability. Impact on project scope, time and/or cost is immediately communicated to our client.

A new client came to Prosin to develop a novel looking deodorant case. The team at Prosin Molds came up with a product design that demanded a complicated parting line arrangement. After the design was approved, Prosin produced the prototype molds for the entire package, including the body, elevator, platform and cap. Upon completion of the product's development, Prosin went on to build all the production molds for the program. Our efforts resulted in the client getting their idea to market in less than 5 months.

Who better than a mold maker experienced in product design to bring your products to market faster?

At Prosin, we can also economically meet your specific production requirement by offering either small, single face molds or large, multi-cavity stack molds for demanding packaging applications.

Recently, a client had to increase their output of a part that had complex surfaces and numerous shut offs. Prosin supplied a mold that ran 20% faster with double the number of cavities. The mold was delivered on time and went into production immediately after a planned adjustment was made to arrive at final sizing.

A high level of mold design expertise combined with very precise machining is required to ensure a mold will produce complex components within their specified tolerance and remain flash free.

Our expert team of mold design engineers working in 3D Solid Works, develops leading edge mold designs that ensure high performance and reliability. Our state of the art manufacturing capabilities produce fully hardened tooling within tolerances of 0,005 mm (.0002”). This not only produces quality parts, but allows for complete component interchangeability; necessary to meet the high volume demands of the packaging markets.

Proven Innovation

Chronic cracking in an oral device from a competitor's mold had increased over time to the point where the scrap rate had reached 90%. The client called on us to come up with a solution that would eliminate this issue in a new mold. Prosin's guaranteed approach successfully resolved the problem and at the same time, reduced the mold size so it could fit into a smaller molding machine.

Reliability = On Time Mold Delivery plus On Time Mold Start Up

A new client manufacturing disposable medical components, expressed surprise when our first mold for them produced parts that could immediately be sent to Quality Control after its first test. The parts quickly passed the QC tests and the mold went into production months ahead of the client's scheduled start up date.

In today's competitive environment, delivering a mold on time is not good enough. Time to market is critical so the mold start up must be predictable. A high level of mold design expertise combined with very precise machining is required to ensure a mold will produce components that are within their specified tolerance and are flash free.

Our expert team of mold design engineers working in 3D Solid Works, develops leading edge mold designs that ensure high performance and reliable start ups. Our state of the art manufacturing capabilities produce fully hardened tooling within tolerances of 0,005 mm (.0002”). This not only results in quality parts at the initial start up, but allows for complete component interchangeability; necessary to meet the high volume demands of the disposable markets. These capabilities also include the mold polishing skill necessary to meet optical grade molding surface finishes required in petrie dishes and well plates.

|

||||||||||||||||||||||||||||||||||

| Hosted and Maintained By |