ELECTROSTATIC OIL CLEANER, VACUUM DEHYDRATION UNIT |

|

|

|

|

Pune Energy Control Devices Pvt. Ltd. is a leading manufacturer of microcare electrostatic oil cleaner, super cleaning equipment for hydraulic and other oils used in Industry. This machine is an off-line cleaning system that removes contaminants down to 1 micron. It works on the principal of electrostatic precipitation. The regular use of this machine enhances the oil change period and the life of the various components used in the hydraulic system. The oil can be cleaned to NAS class 5 by using this machine. The major clients of this product are steel and steel processing industry, engineering industry, plastic injection molding, automobile and auto-components, power plants, cement plants, etc. We have sold over 500 machines till date and our major clients include Mahindra, Tata Motors, Tata Power, Bajaj, Jindal Iron, BHEL, Bokaro Steel, Hindalco, JSPL, Raigarh etc. Another product added in 1999 was microcare vacuum dehydration unit for removal of moisture from oil. We also export these machines to UAE, Bahrain, Pakistan, Malaysia, UK and Africa.

The company was started in 1994 for Supply, installation and commissioning of Diesel Generating sets with Kirloskar, Cummins engines. We carried out the supply/installation of SUDHIR DG sets powered with Cummins engines till 1999. Presently authorized dealer for F G Wilson gensets manufactured by F G Wilson Engineering Co Ltd., U.K. who are one of the largest manufacturers of DG sets in the world. The different customer sectors handled are Hospitals, commercial buildings, industries, telecom sector, software companies, co-operative sector, etc. We have sold value-added gensets like soundproof gensets, multiple gensets with PLC based AMF, auto synchronising and load sharing systems. Consultancy for engineering of heavy fuel oil fired gensets for Captive Power Plants with Co-generation systems.

|

|

Electrostatic Oil Cleaner - Innovative way of Improving Quality & Productivity |

|

Electrostatic Oil Cleaner - Advantages:

• Reduction in oil replacement cost

• Reduction in machine downtime

• Improves life of the hydraulic system components

• Ensure sun-interrupted manufacturing process

• Lower rejection rate

|

Types of Fluids Cleaned

• Hydraulic Oil

• Turbine Oil

• Bearing Lubrication Oil

• Straight Cutting Oil

• Any other non-conductive Liquid

|

|

User Industries

• Plastic Injection Moulding

• Extruding & Pressure Die-casting

• Hydraulic Presses

• General Hydraulics / Servo Valves

• Turbine Control and bearings

• Hot & Cold Rolling Mills

• Precision Machine Tools

• Earth moving, Construction & mining equipments

• Cement Plants

• Power Plants

|

Electrostatic Oil Cleaner - Salient Features

• Removes all suspended contaminants down to 1 micron size

• Low energy consumption & operating cost

• Pollution free process

• Trolley mounted portable unit

• Maintains original properties of Liquid being cleaned

• Unattended operations after initial start up

|

Principle of Operation

MICROCARE is an electrostatic super cleaning equipment involving removal of suspended contaminants in fluids / oils and collecting them on an enormously spread surface of die-electric media.

|

Highlights of Electronic Control Panel

• Total operation control with one key switch

• Continuous monitoring of high voltage & load current

• Reduced electrical components and wiring

|

|

|

Components of the Kit

• Graduated Test Tube

• Graduated Glass Cylinder

• Membrane Filter

• Membrane Holder

• Rubber Grommet

• Titration Flask

• Clamp

• Vacuum Pump

• Rinsing Bottle

• Wooden Box

• Picker

• Moisture testing gun |

Contamination Checking Kit

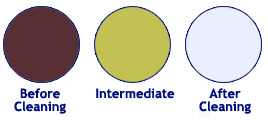

The results of oil cleaning are checked using this kit supplied with the machine. This is a comparative test based on the patch test carried out on 0.8 micron membrane filter for dirty & clean oil.

|

|

Patch Test Report and Kit |

|

|

|

|

|

Vacuum Dehydration Unit |

|

A Complete oil cleaning solution removing free, as well as dissolved moisture, entrapped gases & air.

A positive step towards safeguarding oil & related equipment through timely removal of moisture.

|

|

Vacuum Dehydration Unit - Advantages

• Prevents oxidation & extends oil change period

• Prevents excessive wear of machine components

• Maintains original properties of Oil

|

Vacuum Dehydration Unit - Salient Features

• Removes traces of moisture, dissolved air & gases

• Indirect & controlled heating of oil

• No loss of oil yielding 100 % recovery after dehydration

• Pollution free process

• Trolley mounted portable unit

• Unattended operation after initial start up

• Maintains original properties of fluid being dehydrated

|

|

Liquids that can be dehydrated

• Hydraulic Oil

• Lubricating Oil

• Transmission Oil

• Straight Cutting Oil

• Gear Oil

• Any other synthetic/mineral oil

|

User Industries

• Diesel, Hydel & Thermal Power Plants

• Heavy duty earth moving / mining machinery

• Die-casting machines

• Injection / blow Moulding machine

• Hot & Cold rolling mills

|

Principle Of Operation

Gently heated oil is injected into a vacuum chamber thus extracting dissolved moisture, air and gases from the oil at 450C to 550C. |

|

|

|

|

|

|

| Some of our Valued "Customers" who are Microcare Users |

|

Plastic

• National Plastics Ltd.

• Anchor Kenwood Electricals Ltd.

• Cello Group of Companies

• Exotech Plastics Ltd.

• Gaurav Agroplast Ltd.

• Today's Writing Products Ltd.

Cement manufacturing

• Vasavadatta Cements Ltd.

Steel manufacturing

• Bokaro Steel Plant

• Durgapur Steel Plant

• Jindal Iron & Steels Ltd.

Engineering

• Kalyani Brakes Ltd.

• Bharat Heavy Electricals Ltd.

• Ingersoll Rand Ltd. |

Automotive

• Bajaj Auto Ltd.

• Mahindra & Mahindra Ltd.

• Tata Engineering & Locomotive Co. Ltd.

Power Plants

• Triveni Engineering & Industries Ltd.

• Tata Electric Company Ltd.

Non-Ferrous metal manufacturing

• Indian Aluminium Ltd.

• Swil Ltd.

Earth Moving Equipments

• Sanghvi Movers Ltd. |

|

|

| Electrostatic Oil Cleaner | Vacuum Dehydration Unit |

|

|