Flytech Engineering - Single Screw Segmented Extruders, Twin Screw Extruder Plant for Compounding, Colouring, Recycling and Profile Extrusion |

|

|

|

| |

|

| |

|

| |

We design and manufacture with latest technology for polymer processing

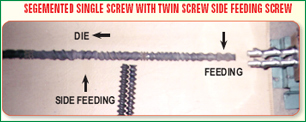

machine for Segmented single screw with vented and twin screw side feeder

Twin screw co-rotating extruder plant with complete up stream and down stream equipment.

We can offer you the range of following custom designed energy saving polymer plant and machinery for 5 to 1300kg/hr in to the following.

Compounding

Colouring

Recycling

Film

Profiles extrusion like pipe, channels for RPVC, HDPE etc.,

Segmented means fully segmented, Barrel and screw. Higher efficient in house produced twin and single helical gearbox with right quality thrust bearings. You can process any engineering plastics with or without filler.  |

|

|

| |

• We Make Specialized line for wood Polymer Processing Twin Screw Extruder

• Twin Screw Extruder (Model: FUE)

• Segmented Single Screw Extruder (Model: FKE)

• Side Feeder (Twin Screw)

• Vertical Feeder

• Air Knife

• Pelletize

• Vacuum-degassing system

• Liquid injection system

• Volumetric Feeder (single & Twin type)

• Loss-in-Weight Feeder (Single & Twin type)

• Spare Screw Element and Barrels |

| |

|

| |

Twin Screw Extruders |

| |

The optimized screw geometry offer the better possible processing of engineering plastics with high disposability and good homogenous products mix.

• Twin Screw Shaft

• Co-rotating - intermeshing

• Dispersion by kneading

• Helical path mixing

• Reverse Element

• Left and Blister action |

| |

Control Panel

In all our extruders AC Inverters with good PID controllers.

SSR Controlled High density cartridge heaters and barrel cooling by AIR & Water or Stream

|

| |

| |

Segmented Single Screw Extruder with vent and Feeder |

Capable of processing any engineering plastics material with fillers. While processing by the vent using vacuum device it can remove volatile gases by the process of de-gassing, so the output material will be produced desired quality level.

|

|

Auxiliary Equipments |

• Volumetric feeder "single and Twin Screw type"

• Loss in weight - custom designed

• Side feeders, vertical feeders

• Liquid injection systems

• Hydraulic screen changer

• Conversion of your existing optimized die head |

|

| |

|

| |

Twin Screw Shaft |

| |

• Co-rotating - intermeshing

• Dispersion by kneading

• Helical path mixing

• Reverse Element

• Left and Blister action |

|

|

|

Flytech Design gives flexibility in your raw material requirements to change your formulation easily to make sure the product quality and repeatability.

We Strongly believe in Commitment, Quality, Technological Excellence, Professional approach.

|

| |

Products: Twin Screw Extruders | Control Panel | Single Screw Extruder | Auxiliary Equipments |

Twin Screw Shaft |

|

|