|

Grinders |

| |

Injection Moulded Scrap Grinders - Suitable for grinding of all thermoplastics, Nylon, Delrin. San, Polycarbonate, ABS, Glass Filled etc. |

| |

|

| |

|

| |

Blow Moulded Scrap Grinders - Suitable for grinding of HDPE, PP, PVC, Polycarbonate, Blow Moulded Scrap, flashes etc. |

| |

|

| |

|

| |

Pipes/Profiles Scrap Grinders -

Standard models are available with built-in Chute for feeding of long scrap of PVC/HDPE pipes & extruded profiles. Standard models available for pipes upto 200mm or even more, to suit your requirements. |

| |

|

| |

|

| |

Films Scrap Grinders -

Suitbale for grinding of LDPE, HDPE, LLDPE, HM, PP, PVC, BOPP, Polyester film scrap. |

| |

|

| |

|

| |

Pet Bottles Preforms Grinders -

Suitable for grinding of PET Bottles,Jars and Preforms. Well proven machines in use across the country |

| |

|

| |

|

| |

Rafia Tapes Monofilaments Grinders - Suitable for grinding PP, HDPE, Nylon Tapes and Monofilaments. |

| |

|

| |

|

| |

Pet Bottles Preforms Grinders -

Suitable for grinding of PET Bottles,Jars and Preforms. Well proven machines in use across the country. |

| |

|

| |

|

| |

Rafia Tapes Monofilaments Grinders -

Suitable for grinding PP, HDPE, Nylon Tapes and Monofilaments |

| |

|

| |

|

| |

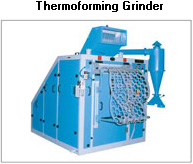

Thermoforming Sheet Scrap Grinders -

Suitable o\for grinding of HIPS, PVC, PP. PET, Thermoforming Sheet Scrap. |

| |

|

| |

|

|

Tumbling type Plastic Dry Color Mixers -

Suitable for mixing of granules with Pigment Masterbatches,Liquid Masterbatches. Can also be used for homogeneous mixing of grinding and virgin materials |

| |

Special Features: |

| |

|

The vessels are made from Heavy guage of S.S. 304 sheet |

|

Vessels are also fitted at an angle for better and faster mixing |

|

Geared motor drive for lesser power consumption |

|

Protective Fence with Safety Interlock |

|

Offers consistent material mixing |

|

Standard models available from 25 kgs./batch upto 300 Kgs./batch |

|

| |

|

| |

|

|

Plastic High Speed Mixers -

Suitbale for preheating plastic materials and for removing moisture. Vessel is of MS Construction. Click on the thumbnail below for a detailed view. |

| |

|

| |

|

|

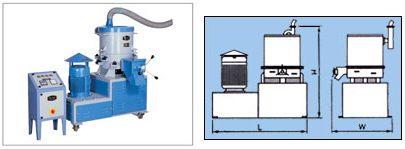

Plastic Films Agglomerators -

The above machine is ideal to convert Film Scrap of LDPE, HDPE/HM, PP, BOPP, Tapes, Rafia, Foam depenfing upon models into the dense cubes for easy feeding into the extruder. |

| |

Available with manual screw type discharge valve. (Pneumatic discharge valve, Exhust blower system and Control Panel are optional and available at extra cost.

|

| |

|

|

Spiral Flow Hopper Loaders |

| |

|

Storage Bin |

|

|

Horizontal Inlet |

|

HDPE Outer Tube |

|

Flexible Spiral Spring |

|

High & Low level Controls |

|

Feeding Hopper |

|

Electric Motor |

|

| |

|

|

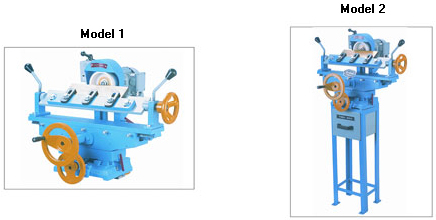

Blade Resharpening Machines - These economical machines increase the life of your blades and give you control over the knife sharpening process. No need to send blades outside for resharpening when you can do them in house. They are very compact and portable and robustly built. They are easy to use with. |

| |

|

| |

|

|

Dust Separating Systems - Glow Industries is proud to be the first in India to introduce a range of Dust Separating Systems. These can be retrofitted on your existing grinders or be fitted on your new Glow Industries Grinder.

Why Separate? |

| |

|

Fines and Dust generated during the grinding process can cause contamination in your processing equipment. |

|

Dust causes Black spots on your moulded product and leads to a lower product quality. |

|

Dust can prove a health hazard. |

|

| |

Principle:

Separation is a simple process. the grinding material is passed through a blower cyclone at high pressure. The pressurized air lifts the lighter dust and fine particles and pushes them out through a separate outlet, leaving the cleaner dust free grinding material to fall through the main outlet.

You can even opt for a single central Dust Separating System to handle all your moulding and grinding machines.  |