Leading Injection Moulding Machines and Solutions Provider - Clamping Unit, Injection Unit |

|

|

|

|

L&T Plastics Machinery Limited is a wholly owned subsidiary of Larsen & Toubro Limited, India's largest engineering conglomerate.

L&T started manufacturing injection moulding machines in 1990 with the introduction of the "D series" of advanced injection moulding machines in a joint venture with Mannesmann Demag Kunstofftechnik, the erstwhile Demag Plastics Group.

In March 2009, L&T acquired the equity formerly owned by Demag to form L&T Plastics Machinery Limited. L&T Plastics is acknowledged as the leading injection moulding solutions provider in India. Its facilities in and around Chennai incorporate some of the most advanced systems for design and research, hydraulics and mechanical construction. Production capacities exceed 1000 machines every year in clamping forces from 400kN to 13000kN.

L&T injection moulding machines enjoy a well established presence in almost every market segment in India. We cater to market verticals of Automotive, Consumer Durables, Electrical & Electronics, Household, Medical Disposables, Packaging, Custom Engineered Components, Writing Instruments, etc.

Solutions offered by L&T would perfectly match the customer requirement and would provide the best value for money.

|

|

|

|

Injection Moulding Machines |

|

| L&T offers high quality precision injection moulding machines in a wide range of clamping force range. The machines are available under Ace Genxt, Aswa and Detech Series. |

|

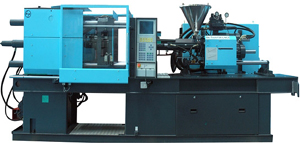

Ace Genxt Injection Moulding Machine |

|

Ace GenXt is a precision, high quality injection moulding machine made by L&T. The modular and ergonomical design enhances economy, reduces maintenance costs, set-up time and spare parts stock requirements, and makes operation more efficient and safer. It offers Clamp force range up to 10,000 KN, Modular options for injection unit, screw, pump rating and drive. With powerful 5-point double toggle, rugged machine construction, and an ergonomic operator interface, it offers competitively priced application packages permitting solutions to be tailored for special jobs.

Ace GenXt Advantages:

Extensive standard equipment

Modular options for tie-bar distance (specific models), injection unit, screw and drive

Competitively priced expansion packages for flexibility and quality

High-strength, compact machine construction

Efficient, operator-friendly layout of components

Icon-control system with touch sensitive operator interface

Freely programmable inputs/outputs

Finely graded modular injection units

Appropriate L/D ratio of screws for flexible use and optimal melt quality

Energy-saving drive through electronic variable volume pump

Features:

Five Point Twin Toggle Clamping System

Modular and Flexible Injection Unit

Powerful and Precise Hydraulics

User-friendly and Precise Control System

|

|

|

Aswa Series Injection Moulding Machines |

|

| Aswa Injection Moulding Machines are available in sizes ranging from 40T to 1000T.

Aswa series Injection Moulding Machine offers excellent performance with its low cycle times and high quality moulded components. Come with an electronically controlled closed loop variable displacement pump which controls the hydraulic pressure and flow directly within the pump. Wide platen areas in Aswa enable larger moulds to be loaded in the machines easily. Availability of T slot platens in higher tonnage machines offers the customer the best fit of the clamping system. The computer optimised and controlled 5-Point Twin Toggle Clamping System in the machines offers fast mould open-close movements and excellent safety for the moulds. Aswa machines are fitted with LNC5 or Ergocontrol as an option that allow very precise control of the moulding parameters. The injection units offer a wide variety of choices for different moulding needs.

|

|

|

Detech Series Injection Moulding Machines |

|

Detech Injection Moulding Machines come in a variety of sizes ranging from 40T to 650T and shot weights from as low as 21 gm to 6.5 kg. They are best suited for mass productions of plastics products with reduced cycle time requirements and for those operations that require returns on capital investment in a short time.

Detech is an entry level closed loop plastics injection moulding machine series offering the best value for money. Detech Injection Moulding Machines have a computer optimised 5-Point Twin Toggle Clamping Mechanism that offers good kinematics and secures the moulds while clamping. Their injection units have a modular selection enabling choice of right machine for specific moulding requirement. The LNC5 control in the machines is best suited for Indian conditions and offers the moulders an assortment of options and features.

|

|

|

|

Injection Moulding Machines and Solutions |

|

| L&T provides injection moulding machines and solutions in a broad range, covering applications of every nature whether it is for the techno savvy high end moulder or a job moulder with versatile needs. Different types of Clamping, Control, Drive and Injection Units are available to suit every application |

|

Clamping Unit |

|

| L&T offers the proven 5-Point Twin Toggle Clamping System. 5-Point Twin Toggle System, known for its quick mold open and close movements coupled with its good mold safety characteristics is one of the most preferred clamping mechanisms in the world. |

|

|

Control Unit |

|

| L&T offers a choice of two different control systems in the machines depending on the application and user needs, the imported Ergocontrol and the indigenously developed LNC5. |

|

|

Drive Unit |

|

| The hydraulic heart of L&T Aswa & Ergotech machines is the electronically controlled closed loop variable displacement pump. The DFE pump provides for extremely fast and precise dynamic flow & pressure control. A second variable pump is offered for simultaneous ejector and core movements to reduce the cycle time. This system can be offered as optional in Aswa as well as Ergotech machines. |

|

|

Injection Unit |

|

| The modular design of injection units in L&T machines offers a wide variety in selecting the right combination of screw & barrel to meet your needs. This is necessary because the plasticizing and injection stages are important and it is a direct measure of the part quality. Special plasticizing units for PET, R-PVC, C-PVC and Thermoset can also be offered with varying designs to meet the processing requirement characteristic of individual polymers. Closed Loop Injection addresses the stringent requirement like the precision and dynamics during the injection stage, this can be offered optionally with fast acting servo valves. |

|

|

|

|

|

|

|

|

| Contact Us |

|

|

L&T-Demag Plastics Machinery Limited |

|

|

Mr. Narayanaswamy (+91 98412 22663 ) |

|

|

Chembarambakkam, Off Chennai-Banglore Highway, P.O. Box No 5, Chennai 602103 |

|

|

+91 44 22497361 |

|

|

+91 44 22492471 |

|

|

|

|

|

www.larsentoubro.com/lntcorporate/common/ui_templates/homepage_news.aspx?res=P_PPM |

|

|

|

|

|

|

|

|