|

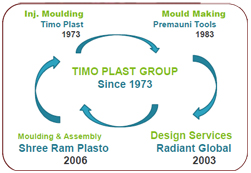

Founded by Mr. Haresh Chandarana in 1973 under the Flagship name of TIMO PLAST as a Custom Injection Moulding Company with a vision to provide solutions to replace Metal Components due to its corrosive nature & Glass Components due to it's brittleness in Critical Applications. Over the past 35 years we have evolved into a respectable group of companies that provides Engineered Solutions around plastics.

We have garnered enough knowledge & deep understanding of the Processing Characteristics of Engineering Thermo Plastics using Injection Moulding. Our domain Expertise lies in Custom Injection Moulding & Product Development Services. We offer Engineering Solutions with Plastics for various industries such as Automobiles, Electronics & Electrical, Consumer Durables & White Goods and Food Packaging & Telecom Industry.

|

Mission

• To Provide Quality Engineering Solutions by replacing raw materials such as metals & glass into recyclable plastics for sustainable growth.

• Enhance Product Design Options, Life & Structural Strength of the Product & Ease of Usage.

• Reduce Piece Part Prices, Product Weight & Raw Material Costs.

Values

• Technology that addresses Customer Needs.

• Innovative Design & Development.

• Moulding ideas into products.

• Open to learning new ideas & feedback from Customers.

Quality Policy

"Follow the Basic Procedures & Processing Characteristics, Quality will Follow"

Vision

• To partner into a Joint Venture with an Overseas Company with Forward Technology, & become a Market

Leader by 2020

• Providing total solutions in Moulding of Engineering Thermo Plastics & Composites Globally.

• To become a TIER 1 Supplier to OEMs of Automobiles, Medical Devices & Aerospace Industry by

capitalizing on our market knowledge, forward technology of the overseas partner & domain expertise of

both.

|

|

|

Product Development & Design Service

• Product Designing is a very important aspect for success of any idea or product for that matter.

• Based on this aspect we focus on development of plastic products using the latest CAD/CAM/CAE software & tools.

• Apart form fulfilling our In-house requirement we also provide Engineering Design Consultancy services for Concept Designing,

Product Engineering, Mould Designing, CAD Modeling, Mold Flow Analysis for various aspects of Injection Moulding, Finite Element Analysis &

Product Lifecycle Management Services.

Mould Making & Product Development

• Our In-house Mould Shop is Equipped with the latest CNC Milling & Machining Centers capable to manufacture moulds to the size

of 2300mm x 850mm

• We have In-house CNC Wire EDM & Spark Erosion Machines

• We also have Grinding, Mould Polishing & In-house Inspection Facilities.

• We are Capable to manufacture Moulds for Injection Moulding Machines Ranging from 20 Tons to 400 Tons.

• Experienced Design Team that uses latest CAD / CAM Software to ensure the utmost feasible Mould Design.

Custom Injection Moulding

• Our forte is providing solutions in Injection Moulding Technologies.

• We have the latest Closed Loop Micro Processor Controlled Machines.

• Along with the machinery the company has invested in technology & skilled work force to develop a highly efficient division that offers

Custom Injection Moulding Services to various Industries.

• Our Machinery ranges form 20 Tons to 400 Tons and are capable to handle Components weighing from 2 grams to 1200 grams.

• We also have in-house Screen Printing, Pad Printing, Spray Painting, Hot Foil Stamping, and Ultra Sonic Welding & Solvent Welding Facilities.

• We are capable to Mould a range of Engineering. Thermo Plastic Materials such as ABS, HIPS, PP, Filled PP, Nylon, PC, PBT, PB etc.

|

|

|