Manufacturer of Injection Moulding & Blow Moulding and Applications - Ferromatik Milacron India Ltd.

Ferromatik Milacron India Ltd. is one of the strategic & important manufacturing bases of Milacron USA, the global leader in plastics processing machinery and manufacturing technologies. With over 120 years of manufacturing experience of Milacron, we bring world-class technology and innovation at your doorstep, helping plastic industry to stay competitive in the ever-demanding global market. Ferromatik Milacron strives to find better solutions to customer needs. Ferromatik Milacron India has pan India presence with offices in Major Cities & Industrial towns to serve the Plastic Industry. We also export our machines to more than 35 countries in SAARC, Middle East & Africa.

Our machines cater to a wide range of Injection Moulding & Blow Moulding end applications like House Ware, Automotive, Thin Wall Container, Electronics & Electrical, Writing Instrument, Industrial Product, Packaging, Consumer Goods, Caps & Closures, PET Preform, Furniture, Construction Fittings... and many more

Vision

Milacron will be a global leader in industrial process, offering products and services so clearly outstanding in terms of innovation, quality, delivery and value that we are consistently the suppliers of choice

Milacron will be a global leader in industrial process, offering products and services so clearly outstanding in terms of innovation, quality, delivery and value that we are consistently the suppliers of choice

We will be driven to FIND A BETTER WAY for our customers and provide growth opportunities for employees, suppliers and shareholders, while adhering to the business philosophy of Total Quality Leadership (TQL) and our core values

We will be driven to FIND A BETTER WAY for our customers and provide growth opportunities for employees, suppliers and shareholders, while adhering to the business philosophy of Total Quality Leadership (TQL) and our core values

Mission

To establish Ferromatik Milacron as a world class business organization comparable to the best in the plastic technology business

To establish Ferromatik Milacron as a world class business organization comparable to the best in the plastic technology business

To participate in global designing, manufacturing and sales activities so as to exceed best industry standard

To participate in global designing, manufacturing and sales activities so as to exceed best industry standard

Our machines cater to a wide range of Injection Moulding & Blow Moulding end applications like House Ware, Automotive, Thin Wall Container, Electronics & Electrical, Writing Instrument, Industrial Product, Packaging, Consumer Goods, Caps & Closures, PET Preform, Furniture, Construction Fittings... and many more

Vision

Mission

Features:

All Axes Movements by Servo Motors results in

Applications

Medical, Electrical & Electronics, Clean Room Application, Writing Instruments, Automotive, Irrigation Components, Packaging

Hydraulic Machines ranging from 80 to 910 Ton

Features

Generous Specification

Generous Specification

Centrally Distributed Force across Platen

Centrally Distributed Force across Platen

High Productivity

High Productivity

User Friendly Control

User Friendly Control

Applications

Furniture, Consumer Goods, House ware, Rigid Packaging, Automotive, Industrial Products

Features

Applications

Furniture, Consumer Goods, House ware, Rigid Packaging, Automotive, Industrial Products

New generation high speed Toggle Machines from 30 to 500 Ton

Features

Rugged & Reliable Design

Rugged & Reliable Design

Precise & Consistent Moulding

Precise & Consistent Moulding

Generous Specification

Generous Specification

Energy Efficient Production

Energy Efficient Production

Wide Combination of Injection Unit with Clamp makes Magna T a Versatile System

Wide Combination of Injection Unit with Clamp makes Magna T a Versatile System

Applications

Packaging Industry, Automotive Industry, Medical Industry, Writing Instrument, Electrical & Electronics, Industrial Components

Features

Applications

Packaging Industry, Automotive Industry, Medical Industry, Writing Instrument, Electrical & Electronics, Industrial Components

Two Platen Machines ranging from 500 to 3000 Ton

Features

Large Tie bar Spacing & Daylight

Large Tie bar Spacing & Daylight

Compact Two Platen Clamping Mechanism

Compact Two Platen Clamping Mechanism

Minimized Footprint

Minimized Footprint

Energy Efficient Production

Energy Efficient Production

Truly Closed Loop System results in Precise Component Moulding

Truly Closed Loop System results in Precise Component Moulding

Applications

Automotive, Consumer Goods, Rigid Packaging Pallet, Industrial Products

Features

Applications

Automotive, Consumer Goods, Rigid Packaging Pallet, Industrial Products

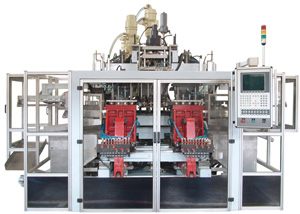

Features

Higher Productivity Reduced Containers Cost

Higher Productivity Reduced Containers Cost

Consistent Container Quality

Consistent Container Quality

Reduced Setup & Startup Time

Reduced Setup & Startup Time

High up Time

High up Time

Reduced Rejection Rate

Reduced Rejection Rate

Reduced Energy Consumption

Reduced Energy Consumption

Applications

Personal Care, Food Products, Home Care, Lubricants, Cosmetics, Pesticides, Edible Oil, Pharmaceuticals

Machine can be configured for...

View Strip Application

View Strip Application

2 Layers & 3 Layer Applications

2 Layers & 3 Layer Applications

Angular Blowing Application

Angular Blowing Application

Applications

Personal Care, Food Products, Home Care, Lubricants, Cosmetics, Pesticides, Edible Oil, Pharmaceuticals

Machine can be configured for...