For Sale - UM - 11607 - Alpha Marathon Bubble Forming Machine

Reference Numbers

UM - 11607Product

Alpha Marathon Bubble Forming MachineLocation

UK

- Air bubble film line

- Finish film width: 1500 mm

- Maximum output: 220 Kg/hr

- Maximum Roll Diameter: 1200 mm

- Material

LDPE: 55%

LLDPE: 25%

HDPE: 20% and blends

Line film trim / Scrap recycling systems including cyclone and feeder

- Venture Trim removal system

- Trim receiver

- High Efficiency Cyclone

- Screw feeder

- Film Grinder

Gravimetric extrusion control system

- Four automatic loaders

- One gravimetric mixer for extruder

- Max total capacity: 220 Kg/hr

Marathorn 75mm Diameter

- 75 mm Screw diameter, 30:1 effective L/D ratio

- Barrel, Screw, Heating/Cooling, Reducer

- Screw speed: 125 rpm

- Pressure gauge with alaram

- Lower barrel height

- Hopper and slide gate

- Rupture disc rated at 520 BAR

- Drawer magnet

Marathon Screen Changer

- Mannual lever type

- Complete with two detachable breaker plates

- Pressure actuated sealing mechansim

Dual orifice flat die with deckling system

- Heavy duty body with back center fed single layer die for flat film

- Dual opening with deckling systems and gap range from 20-100 microns

- Die body heat treated to 28-32 rockwell C with center support

Marathon Extrusion and auxiliary platform

- Two extruder

- flow distributor assembly

- Feed blocks

- Screen changers

- Electronics controls

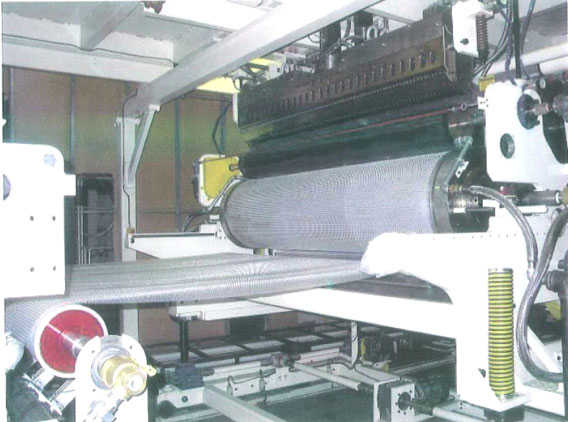

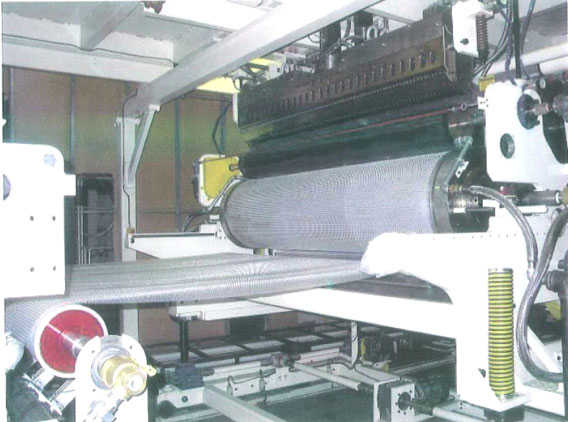

Marathon Face bubble forming cylinder assembly with rollers

- Generating finished web width of 1500 mm with 10 mm bubble size

- 545 mm diameter bubble forming cyclinders with dual wall internal refrigeration

Independent 2.0 HP drive system for forming cylinder

Marathon manual single face turret winder

- 1600 mm roll face width

- 1200 mm max. roll diameter

- Hand rail accessed from steel stair

- Two 3 HP Siemens torque drive systems

- 90 mm diameter aluminum idler rolls precision machined and statically balanced

Vacuum Pump

- 1 liquid ring vacuum pump

- 10 Hp close coupled TEFC 3 PH motor

- Capacity of 16-22 V 252 Torr. at 1750 Rpm

Completer Oil Tempreture Control Unit

- 24 Kw steel sheath heaters, total 48 Kw

- Low watt density

- Fulfio by pass valve to protect heater element and pump

- Pump

96 Ltr per minute at 4 BAR

2 HP positive displacement pump

40 mm delivery and return connections

- Cooling

U tube heat exchanger

Stainless steel tube with a steel shell

- Tank

18 Liter baffled steel expansion tank and reservoir

Marathon Digital Operator Control Panel

- Floor standing control panel including tempreture controller for barrel

- Master drive control including one master speed and individual slaves

- One Soft touch LCD Flast screen

- Nip rollers forward/reverse, open/close controls

- Vacuum power unit on/off button and controls

(For image, Please see next pages.)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}