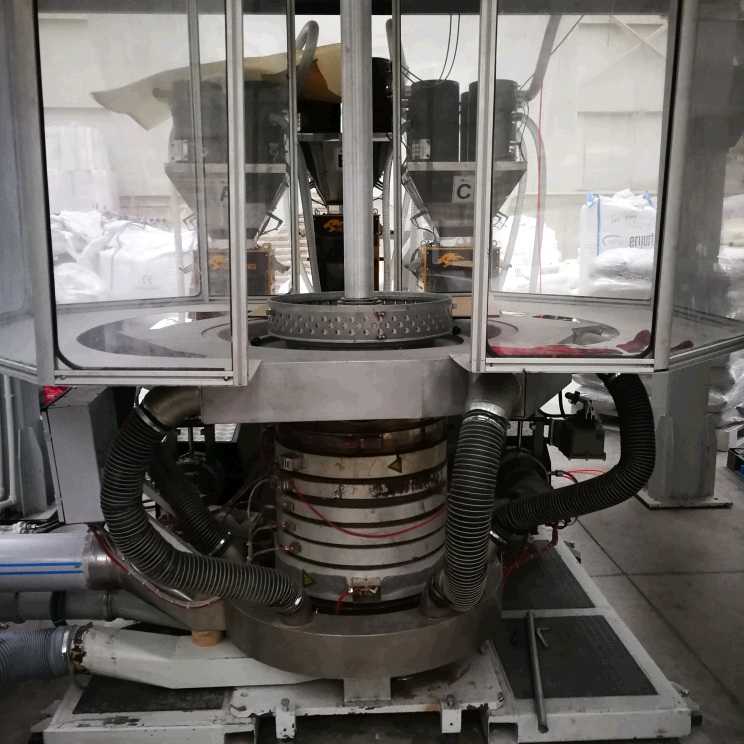

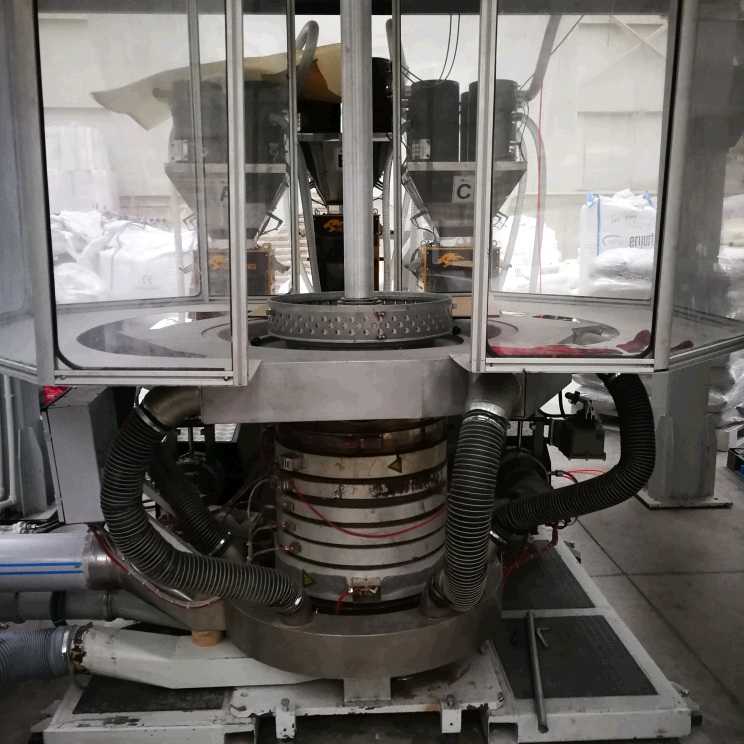

For Sale - UM - 16415 - DIKEY 3 Layer Blown Film Extrusion Line

Reference Numbers

UM - 16415Product

DIKEY 3 Layer Blown Film Extrusion LineYear Of Manufacture

2015Location

TURKEY

Materials : LLDPE / LDPE / HDPE / PP / Borstar / Matalocen / Borcene / recyling

Films: General Purpose Packaging Films, Shrinkable Films,

Lamination Films, Black / White Colored Films, Films for Bag, Printed and Non, Printed films

Extruders: 2 x 55 mm, L/D:1:30

1 x 65 MM L/D.1:28

Die Dimensions (Head): 3 layer Squiral Mandreal Big Body Die

Die Diameter 350 mm

Die Gap 2,2 mm

IBC inner bubble cooling System

Machine Production Capacity (kg/) : 280 kg/h

Actual production can be changed according to raw material type and quality, formulation ratio, operator skill and capability, cooling and envirionmental conditions

Cooling Ring: DIKEY Brand high efficiency , dual-lip airring

Take-Off : 1800 mm, horizontal Rotational Take off unit

Winders: 1800 mm, BACK TO BACK dual winders

Line speed 120 m/min

Roll diameter max 800 mm

Film width 1700 mm

Contact/Surface type winding

3 inç air-expanding shaft

Roll unloading system

THERS SPECIFICATIONS

Raw Material suction, loading and dosing systems (PARS /TURKEY)

Computerized gr/m2 line speed and kgh throughput Control system with integrated supervisory computer (Allen Bradley)

Corona Treater ( Enerkon Turkey)

Web Guide Control with automatic sensor position

3 inç air-expanding shaft

Tower Height 12 metre

Touch Screen Machine Operator Panels

All Automation systems renovated in 2018

Overall die cleaning and chroming completed in 2018

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}