Required - UM - 3815 - 1500 / 2200 ton Injection Moulding Machines

Reference Numbers

UM - 3815Product

1500 / 2200 ton Injection Moulding MachinesLocation

Thailand

We are looking for a 1500 ton and a 2200 ton injection moulding machine

- The machine will be used to add additional capacity to our plant for automotive parts and our industrial products, such as pallets.

- We are looking for should not be more than 10 years old, with exception for very well maintained machines which should itself not be more than 12 years old.

- We very much prefer European, American or Japanese brands.

Parameters important to us for 1500 ton machine

- Distance between tie-bar (H × V): >= 1727 × 1320 mm

- Min. mould height adjustment: <= 500 mm

- Max mould height adjustment: >= 1300 mm

Paramaters important to us for 2200 ton machine

- Distance between tie-bar (H × V): >= 2000 × 1700 mm

- Min. mould height adjustment: =< 700 mm

- Max mould height adjustment: >= 1800 mm

Screw size B will be acceptable for both automotive parts and our industrial products.

Critical requirements:

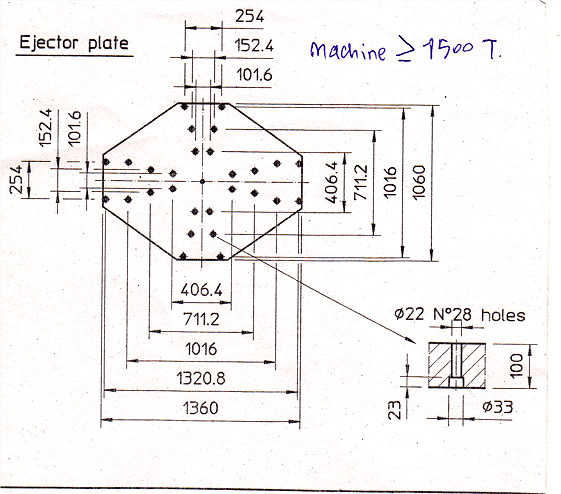

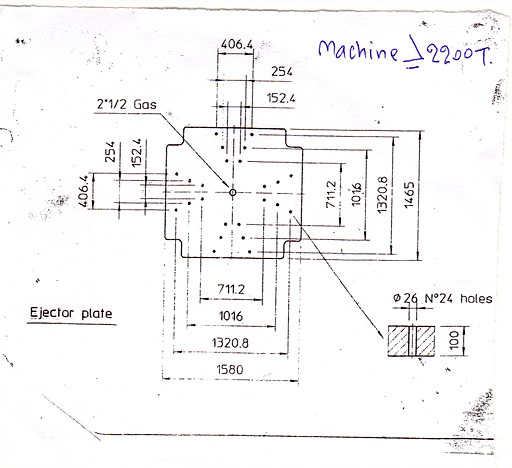

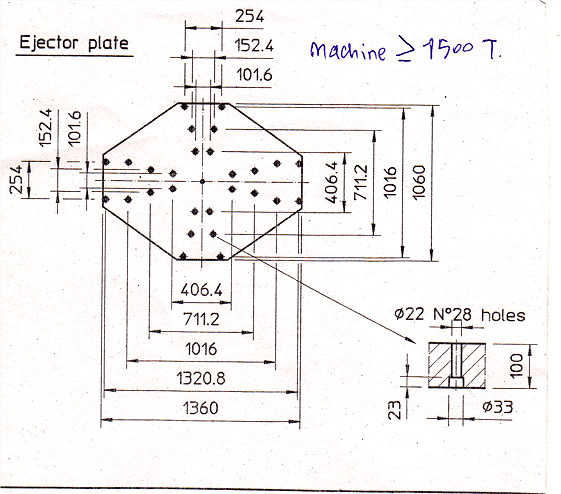

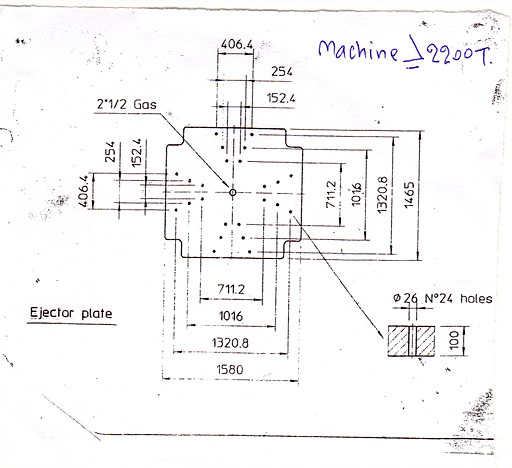

1. Ejector plate drilling according to Euromap (Refer images below)

2. Robot fixing plate drilling according to Euromap

3. Core and Air ejection on the Moving Platen

4. Core and Air ejection on the Fixed Platen

5. Moving and Fixed Platen (T-Slots)

6. Pneumatic (air) and Hydraulic (core) prearrangement for sequential injection

7. Intrusion or cusion (injection)

8. Screw mixing

(For more details, please click next page)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}