For Sale - UM - 4805 - Remanufactured Polycarbonate Sheet Line

Reference Numbers

UM - 4805Product

Remanufactured Polycarbonate Sheet LineLocation

USA

Features

Extruder:

- 4-1/2" Sterling extruder - rebuilt, L/D 36:1

- 78" barrel centerline height having a double vented barrel (one vent presently plugged)

- Including a vent vacuum system. Barrel is

- Electrically heated, closed loop water cooled via cast aluminum heaters w/new control valves.

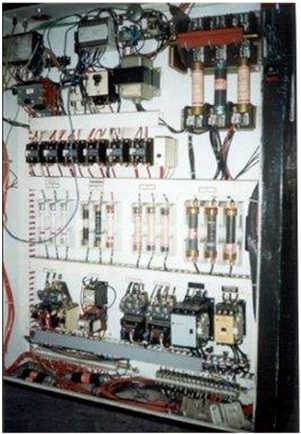

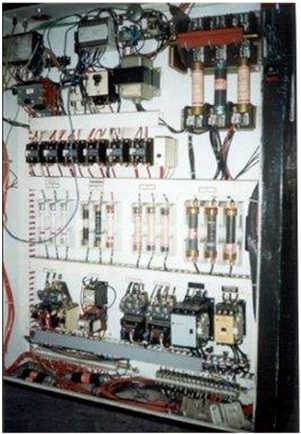

- Temperature control cabinet is free standing w/new wiring.

- Includes 2 spare screws.

Screen changer:

- - 4-1/2" Sterling Hydraulic Slide Plate Screen

- Changer mounted to the discharge end of barrel and includes hydraulic power pack.

Melt pump:

- Barber Coleman 940 Controller.

1) Used 30 HP

- Luwa Melt Pump is included also includes the control Maag 70/70 Thermorex.

Sheet dies:

- 2 Dies included - dies are bottom center fed for 90 degree downward extrusion (cast) 66" Die Johnson w/45 degree restrictor bar withflex lip and dickle bars with removeable lower lip, .001" th to 250'th 60" EDI H75 model .001"th to .075"th dies have been cleaned and new body bolts have been installed in both dies.

Sheet take off:

- Reconditioned 66" face sterling sheet take off having

4) Cooling & polishing rolls mounted in a configuration (cast) whereby the extrude enters

downward between the nip of

2) 8" dia. chrome rolls then wraps around

2) 14" chrome & polished rolls.

- Additional rolls included.

Temperature Control System.

- 2) Dual zone oil temperature control units for cooling chrome & polished rolls

Shear:

- Wysong 72" wide Power Shear for cutting sheet

Sheet stacker:

- Automatically stacks extruded sheet

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}