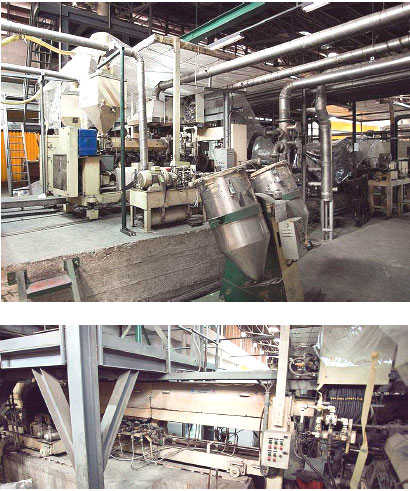

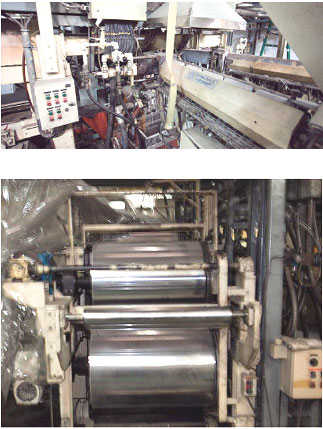

For Sale - UM - 8765 - 4200 mm Cellier BOPP Co-extrusion Line

Reference Numbers

UM - 8765Product

4200 mm Cellier BOPP Co-extrusion Line

Include ATLAS Primary Slitter Rewinder, 4,200 mm

Several upgrades with new PLC System

Chill roll and DIE and gauging system

DIE Type, make & model. No. of Bolts, Auto or manual.

- DIE Type = PERF. METAL 3", Widex50"LG

ALUM. CHANNELS 7/8"x2.1/4"x50"LG

ALUM. ANGLE (saw cut)1"x3"x3.1/4"LG

- EXTRUSION DIES brand, Chippewa Falls, WI U.S.A

- No. of Bolts = 19 SET,1 Phase, 240Vac, 200W/SET

- It is a manual operated

Thickness gauge system, make & model.

- Web gauge is YOKOKAWA brand, Model WG8PC2 installed in 1994.

- Air Knife system.

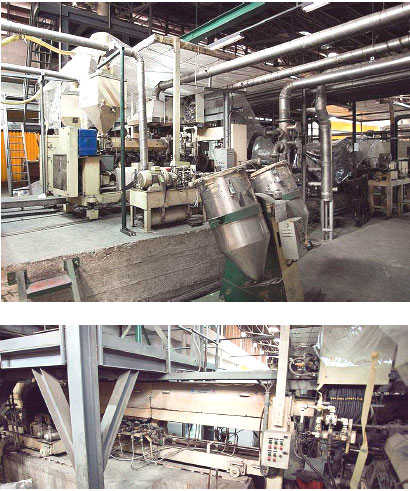

1 Main Extruder: DAVIS STANDARD

Screw Diameter 170 mm

2 Satellite Extruders: Screw Diameter 70 mm

MDO

1. MDO pump flow rate, is Preheating, Stretching, cooling, and annealing. Mode heating .

- MDO pump flow rate = 600 L/Hr (hot oil.).

- Temperature = 130 c ,at Stretching = 4150 mm.

- Number of MD rolls: 14 rolls totally that divide to 4 heating zone X

- 2 rolls each, 2 stretching zone 2 ollas each and 1 stabilize zone with 2 rolls

TDO.

1. No of Chain clip . Both sides approx. 1042.

- Chain clip is 521 set (left section).

- Chain clip is 521 set (right section).

- Latest overhauled at 4/11/2003 years such as clip

- TDO: Devide to 8 zones with 2.79 m long per each zone

2. Returning of chain from out side of the TDO or inside the oven. Sliding see tech. 4.1.2

- inside the oven.

3. Chain is capable for thickness from

- 12 to 40 micron.

4. Min. and maximum stretching width of the chain.

- Min = 4000 mm.

- Max = 4200 mm.

5. Make of TDO chain.

- Cellier, France.

6. Gear Box detail of

- Extruder model 60IN60TP IH, SER No.L4370 S.O. No.03995 With S.F.

1.50, RPM 100, GEAR RATIO 17.21 MANF. = 1 set

- No Melt pump

- Chill roll No. 405 9020 . 002 . 1, CDA 120 T2 860 Nm., N1 591 min N2

11.33 min. = 1 set

- TDO No. 403 811 005-2-1 CFA 225 T2 3490 Nm. N1 1720min N2 52.55 min.

= 1 set

- Pull roll No. 403 812 083 1, CDA 120 T2 314 Nm., N1 1533 min N2 143.75

min. = 1 set

- Corona down No. 457 007-002-1, CDA 120 T2 353 Nm., N1 1696 min N2

123.3 min. = 1 set

- Corona up No. 403 801 049-3-1, CDA 80 T2 173 Nm., N1 1612 min N2

127.23 min. = 1 set

- COOLING ROLL No. 3480346739, Type Z48A 112 MA 4, 380Vac, cos

0.82,4 kw, N1 1440 min N2 280 min, I:5.15.

= 1 set

- WINDER MAIN Reduction CR 60.M0, No 790577/1

REDUCTION 60 tr/mn. = 1 set

- WINDER Adapter Reducteur CR.C1.02.B5 , No 790577/1

REDUCTION 3.2 tr/mn. = 1 set

7. Heating capacity and heaters type.

- hot oil type

8. Mode of heating.

- PID controller.

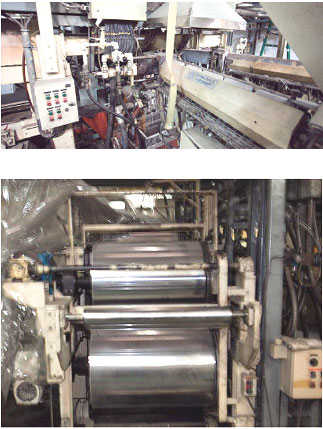

PULL ROLL.

1. No. pull roll at out of TDO

- It is a 1 pull rolls stand (roller at 2 set )

DC motor 16.2 KW = 1 set

Corona treated make, and condition

- Sherman Treater 25 KV(maximum)

Winder type and make

- Cellier, France.

- Winder motor DC, 6KW x 2(core A, core B) = 1 set Winder PLC, LG Brand

programmable logic controller model GLOFA GM3/4 Series.

DC drive is digital.

Trim conveying system, make, model and capacity.

- Cellier, France. Inline system.

What is the capacity required for recycle plant.

- Inline recycle system.

- AC Grinder + Cutter 8.5 KW = 1 set

Primary slitter system, make, model, capacity, 3 inch or 6 inch paper core. Rewinding roll diameter

max. size.

- ATLAS Primary slitter is Atlas. Made in England.

- Paper core 3 inch and 6 inches

- Min width cutting 350 mm.

- Max width cutting 2000 mm.

- Max cutting 9 Roll / Set.

- Rewinding roll diameter max = 1025 mm.

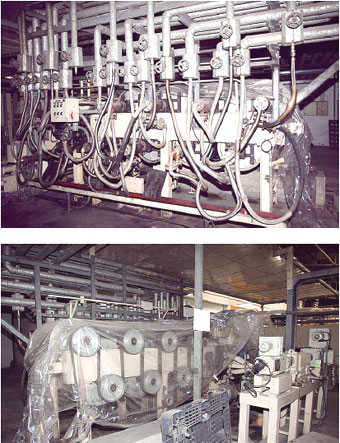

Electrical panel and DC drive.

1. DC drive and PLC make, model.

- PLC line BOPP, Telemecanique Brand, model PMXP67425,

- Power supply card TSXSUP702,

- Analog input TSXAEM411 and TSXAEM811,

- Analog output TSXASR200,

- Digital output TSXDS1635,

- Digital input TSXDET1612 and TSXDET3242.

DC motors details, make capacity (up date in year 2009)

- Main Extruder YASKAWA Brand, 300KW, 440 V (ARM),725-726 I(ARM),150V(F), 18-21

I(F), 1300-1500 RPM. = 1 set

- Satelite Extruder1 LEROY Brand, 16.2KW, 440 V (ARM),43 I(ARM), 340 V(F), 1.7 I(F),

2370 RPM. = 1 set

- Satelite Extruder2 LEROY Brand, 16.2KW, 440 V(ARM),43 I(ARM), 340 V(F), 1.7 I(F),

2370 RPM. = 1 set

- CHILL ROLL SICME Brand, 5.3KW, 400 V(ARM),17 I(ARM), 310 V(F), 3.44 I(F),

1,760 RPM. = 1 set

- MDO 1 LEROY Brand, 16.2KW, 440 V(ARM),43 I(ARM), 340 V(F), 1.7 I(F), 2370 RPM.

= 1 set

- MDO2 LEROY Brand, 40.2KW, 440 V (ARM),103 I(ARM), 170/340 V(F), 16/3 I(F), 1700

RPM. = 1 set

- TDO LEROY Brand, 95KW, 440 V(ARM),241 I(ARM), 340 V(F), 4.5 I(F), 1795 RPM. =

1 set

- PULL ROLL LEROY Brand, 16.2KW, 440 V (ARM), 43 I(ARM), 340 V(F), 1.7 I(F), 2370

RPM. = 1 set

- WINDER A+B LEROY Brand, 6.5KW, 440 V(ARM), 21.5 I(ARM), 170/340 V(F),

3.88/1.94 I(F), 940 RPM. = 1 set

Electrical panel MCC and PCC included in this scope.

Heating oil, temp, heat load of each equipment.

At width 4150 mm

- Thickness 20 micron.

Main Extruder

- Screw barrel heater 5 ZONE

- Adaptor heater 1 ZONE

- Filter heater 1 ZONE

- Melt pipe heater 3 ZONE

Satellite Extruder 1

- Screw barrel heater 4 ZONE

- Filter heater 2 ZONE

- Melt pipe heater 3 ZONE

- Filter heater 1 ZONE

- Melt 1 ZONE

Satellite Extruder 2

- Screw barrel 4 ZONE

- Filter 2 ZONE

- Melt pipe 3 ZONE

- Melt filter 1 ZONE

- Melt 1 ZONE

- DIE: Heater 5 ZONE

- MDO: Hot oil 7 ZONE

- TDO: Electrical heater 8 ZONE

- It is the thickness range 12 micron - 40 micron, Final jumbo width at 4200 mm.

2. The design capacity of plant at 20 micron basis.

- The plant capacity at 20 micron basis is 10.8 tons / day.

3. Utilities included in the scope also mention the capacity required for

chiller, hot oil system, air compressor, cooling water, etc and building requirement for the

same.

Chiller

- UNI-AIR Brand , model SACU-CHB-060, power 30 HP (2).

555,000 BTU, 46 Tons = 1 set.

- UNI-AIR Brand, model SACU-CHB-050-CC, power 20 HP (2)

400,000 BTU, 33 Tons =1 set (Spare).

Hot oil. Type Horizontal

- Cellier Brand, 6 bar, 380 VAC, GME 30KW, 125L = 5 set.

- Cellier Brand, 6 bar, 380 VAC, GME 20KW, 65L = 2 set.

Air Compressor Atlas copco Brand, GA18 model, 18 KW,

- Pressure operated 6-7 Bar,96 cfm = 1 set

Air Tank capacity 500 liter = 1 set

Cooling water.

- Extruder+ Pull roll CALPEDA Brand pump, 7.5KW,380 VAC

= 1 set

- Cooling tower pump 4 KW 380VAC.

= 1 set

- Softener CALPEDA Brand pump, N20/125, 495W,380 VAC

= 1 set

- Exchanger water bath CALPEDA Brand pump, N32/200.

495W,380 VAC = 1 set

- Cooling roll CALPEDA Brand pump, N50/250,5.4HP, 380 VAC =

1 set

- Chiller Pump CALPEDA Brand pump, N65/250 6.5HP, 380VAC. = 1 set

- Chiller Pump CALPEDA Brand pump, N40/160 4KW, 380 VAC.

= 1 set

- Chill roll CALPEDA Brand pump, N50/125, 5.4HP, 380 VAC

= 1 set

4. What up gradation done from the year 1988.

- Up grade after the year 1988, such as

1. Upgrade winder control unit in Jun 2000,, LG Brand

Programmable logic controller model GLOFA GM3/4 Series.

DC drive is digital.

2. Included pull roll ( cooling roll) modified at year 2000,

such as 4200x300 mm. and AC motor 3.7 KW, inverter

controller.

(For images, please see next pages)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}