- Heavy duty single piece slant bed casting High rigidity, high precision spindle ( RPM 3500 max ) with high torque 15/18.5 KW Motor

- Fast indexing 10 station hydraulic tool turret

It is used for precision turning of components like Die head parts, Punches and Cavities Scroll Cams, giving excellent repeatability and consistency of profiles.

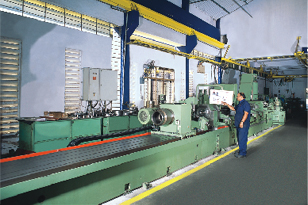

Tibo Loch Deep Hole Drilling Machine (German Make)

Tibo Loch Deep Hole Drilling Machine (German Make) with capacity for solid drillig of dia. 18 -120mm, Counter drilling of dia. max.250 mm, Drilling depth of max.4000 mm/4300 mm stroke and job accommodation of 750mm dia./4300mm length.

This compact, high precision machine has doubled the production capacity of both Single and Twin Bore Barrels resulting in much faster delivery.

TBT Deep Hole Boring Machine

TBT Deep Hole Boring Machine with extended capacity upto 5 metres deep is used for accurate boring of Single and Twin Barrels.

Wanderer Screw Cutting Machine

Wanderer Screw Cutting Machine - an accurate, advanced machine for accurate cutting of screws

Gas Nitriding Furnace 4 Nos.

Gas Nitriding Furnace 4 Nos. which includes one of 5.2 metres -

the deepest in India - for nitriding of various components.

Mitutoyo Co-ordinate Measuring Machine (Japan Make) - The latest machine for quality control

checks for the dimensional accuracy of components. It checks all three dimensions of a component in one seting. It improves the dimensional accuracy of components of Thrust bearing housing, Split housing, Barrel adaptor, Barrel Flange, Haul- off components, Die components etc..

Other CNC Machines

Other CNC Machines for cylindrical grinding, Screw miling, barrel machining and other critical functions.

Enchanced Technical Capabilites

The sophisticated manufacturing and engineering capabilities provided by these machines has enchanced KET's abilities to provide customers with high tech, high quality plastics extrusion machinery which gives them

faster return on their investment.