Polymers are synthetic

and natural macromolecules composed of smaller

units called monomers. Many synthetic polymers

are produced and utilized because they are

resistant to chemical and physical degradation.

These polymers resistant to degradation present

disposal problems when their usefulness ceases.

Research has shown that substitution of natural

monomers into synthetic polymers produces

polymers that are more easily biodegraded.

A biodegradable polymer

is a polymer in which the degradation results

from the action of naturally occurring microorganisms

such as bacteria, algae or fungi. These biodegradable

polymers are largely used in medical application

where they undergo degradation by chemical

hydrolysis.

Polymers prepared from glycolic acid and lactic acid has found a multitude of uses in the medical industry, beginning with the biodegradable sutures first approved in the 1960s. Since that time, diverse products based on lactic and glycolic acid�and on other materials, including poly(dioxanone), poly(trimethylene carbonate) copolymers, and poly (  -caprolactone) homopolymers and copolymers �have been accepted for use as medical devices. In addition to these approved devices, a great deal of research continues on polyanhydrides, polyorthoesters, polyphosphazenes, and other biodegradable polymers.

-caprolactone) homopolymers and copolymers �have been accepted for use as medical devices. In addition to these approved devices, a great deal of research continues on polyanhydrides, polyorthoesters, polyphosphazenes, and other biodegradable polymers.

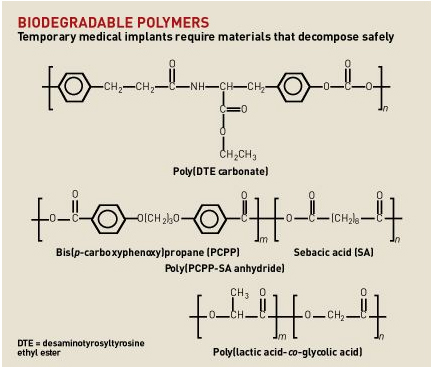

Some examples of the biodegradable polymers are shown below.

• There may be a variety

of reasons, but the most basic begins with

the physician's simple desire to have a device

that can be used as an implant and will not

require a second surgical

intervention for removal.

• Besides eliminating

the need for a second surgery, the biodegradation

may offer other advantages .

For example, a fractured bone that has been

fixated with a rigid, nonbiodegradable stainless

implant has a tendency for refracture upon

removal of the implant. Because the stress

is borne by the rigid stainless steel, the

bone has not been able to carry sufficient

load during the healing process. However,

an implant prepared from biodegradable polymer

can be engineered to degrade at a rate that

will slowly transfer load to the healing bone.

• Another exciting use for which

biodegradable polymers offer tremendous potential

is as the basis for drug delivery

, either as a drug delivery system

alone or in conjunction to functioning as

a medical device.

• Biodegradable materials may be

the only option for some potential applications.

For example, reconstructing functioning

blood vessels requires materials

that degrade in the body, because nondegradable

scaffolds occupy too much volume to allow

tissues to regrow completely.

The general criteria for selecting a polymer

for use as a biomaterial are to match the

mechanical properties and

the time of degradation to the needs of the

application. The ideal polymer for a particular

application would be configured so that:

- It has mechanical properties that match

the application, remaining sufficiently

strong until the surrounding tissue has

healed.

- It does not invoke an inflammatory or

toxic response.

- It is metabolized in the body after fulfilling

its purpose, leaving no trace.

- It is easily processable into the final

product form.

- It demonstrates acceptable shelf life.

- It is easily sterilized.

Significant commercial use of biodegradable

polymers:

Sutures.

Of the total medical biodegradable

market, this is a mature area expected to

grow rapidly in the future. About 125 million

synthetic bioabsorbable sutures are sold each

year in the United States. They are divided

into braided and monofilament categories.

Braided sutures

are typically more pliable than monofilament

and exhibit better knot security when the

same type of knot is used . Monofilament

sutures are more wiry and may require

a more secure knot. Their major advantage

is that they exhibit less tissue drag, a characteristic

that is especially important for cardiovascular,

ophthalmic, and neurological surgeries.

There are eight objective and three subjective

parameters for suture selection

based on criteria such as tensile

strength, strength retention, knot security,

tissue drag, infection potential, and ease

of tying. SYNTHETIC

degradable sutures have been available commercially

since the 1970s. Originally made from polyglycolic

acid (PGA), early versions of the products

degraded and lost their mechanical strength

in just two to four weeks--too fast for some

applications. To broaden the range of uses,

alternative sutures were

made from copolymers of PGA and a more hydrophobic

compound, polylactic acid (PLA). PLA's hydrophobicity

limits the extent of water uptake in the copolymer,

which in turn reduces the rate at which the

polymer backbone is hydrolyzed relative to

PGA.