|

Around Thanksgiving

of 2002, two scientists from Rutgers University, along with few

others, built a 56 feet wide, one lane bridge in only 11 days. This

bridge on Mullica river in Southern New Jersey is made from plastic

I beams produced by a company called Polywood. Only zinc-coated

steel fasteners and wooden piles, remains from the bridge's wooden

predecessor were used along with the plastic I beams. This bridge

cost about US$ 75,000 compared to US$350,000, the cost of a conventional

wooden bridge. The weight of this new bridge is also much lower

compared to the conventional wooden or metal and concrete bridge.

Thomas J. Nosker and Richard W. Renfree, the Rutgers engineers,

came up with the plastic unexpectedly. They had been experimenting

with two common kinds of plastic: high-density polyethylene (HDPE),

used to make such items as milk containers and detergent bottles;

and polystyrene (PS), commonly used in coat hangers and disposable

eating containers.

Neither material alone is suitable for making bridges. HDPE is

not stiff enough, and polystyrene, while stiffer, is too brittle.

At the time the two researchers were doing their experiments, nothing

suggested that the combination of these two plastics would make

a more promising material. Nosker and Renfree, however, found that

one combination -- 65% HDPE and 35% PS, worked unexpectedly well.

With the help of Washington and Lee University engineer Kenneth

Van Ness, the Rutgers team figured out why. It turned out that the

Polystyrene, when added to a cooling batch of HDPE in the proper

proportion, fills the voids in HDPE's sponge-like structure and

stiffens the material considerably.

Though Nosker and Renfree made this discovery in 1988, their finding

attracted little attention for almost a decade. But they persevered,

and around 1996, they began to zero in on bridge construction as

the most

promising application. In 1999, Nosker and Renfree oversaw construction

of a part-plastic, part-steel bridge in Missouri and, two years

later, of a part-plastic, part-fiberglass bridge in New York.

Although the Rutgers University scientists acknowledge that their

technology is not yet ready for use on heavily traveled spans, such

as those in the interstate highway system, they say plastic has

quickly exceeded their expectations as a bridge-building material.

Most notably, they say, their plastic is already technically and

economically competitive with wood, which is used in more than half

a million bridges in the United States today.

The big question is how well plastic bridges will stand up to years

of traffic, said Myint Lwin, director of the federal Office of Bridge

Technology. "There is no credible, currently available way

to predict 50 to 75 years of structural performance from short-term

material test data. The most reliable method now available to predict

performance over the long term is the straightforward -- and slow

-- method of constructing a bridge made from the material and monitoring

its condition over its service life."

What is very interesting that 1 year of this novel bridge is complete

without any problem. If this experiment succeeds it would open up

a new opportunity to utilize the recycled plastic more effectively.

Previous Article

Next Article

Tell Us What You Want

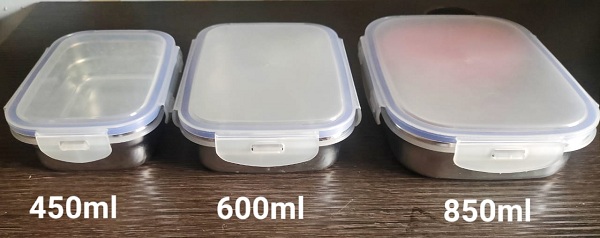

Unused tiffin, lunch box moulds

| | | |