|

3D printing allows manufacturers to develop objects using a digital file and variety of printing materials. The materials used in 3D printing include various types of polymers, metals, and ceramics and similar others. 3D printing offers methodologies that make manufacturing of complex designs an apparent reality. Widespread applications of 3D printing, and the potential prospects of 3D printing in diverse fields would fuel the market growth. The factors driving this market are reduction of errors, high degree of accuracy, efficient use of raw materials, ability to build customized products, simultaneous use of multiple materials for printing, and competency over traditional techniques. On the contrary, high production cost to individual users, expensive 3D printing software, lack of channel partner assistance, and scarcity of skilled labors are some of the key restraining factors for the global 3D printing market. The global 3D printing market is in the progressive phase of its life cycle, valued at US$2811.8 mln in 2014, and is anticipated to reach US$8683.7 mln by 2020, growing at a CAGR of 21% during 2015 -2020, as per Allied Market Research. Based on technology, 3D printing market is segmented into stereolithography, selective laser sintering, electron beam melting, fused deposition modeling, laminated object manufacturing and others. These technologies follow additive manufacturing process in which model is built by adding successive layers of material. Among these technologies, stereolithography is expected to play the most prominent role as it has revolutionized the speed and techniques of designing and manufacturing objects, which has benefited various industries significantly. Based on the input materials, the 3D printing material market is segmented into polymers, metals and alloys, ceramic and others. Polymers are the most extensively used 3D printing material in the current scenario. The 3D printing services market includes application development, installation, and maintenance services. 3D printing has a wide array of applications in various industries, namely consumer products, industrial products, aerospace, defense, automotive, healthcare, education & research and others. Among these industries, consumer products, followed by automotive are expected to be the largest revenue generating sectors. 3D printing is widely used for developing consumer products such as toys, shoes, electronic products, bottles, containers, dishware, mobile phone cases, jewelry, ceramics and similar others.

The 3D printing market is expected to reach US$30.19 bln by 2022, at a CAGR of 28.5% between 2016 and 2022 as per Markets and Markets. The market has been segmented on the basis of printer, material type, material form, process, technology, software, service, application, vertical, and geography. Industrial 3D printers are expected to account for the largest share of the 3D printing market during the forecast period due to the increase in accuracy per inch of part dimension, faster printing speed, and introduction of new materials. These factors have led to the adoption of the industrial 3D printers in various industries such as aerospace & defense, automotive, energy, engineering, and healthcare among others. In addition, 3D printing is now used to manufacture complex components, prototypes (rapid prototyping), and small-series components. Streamlining of production workflow through automated production tools, powder handling and recycling functions, and mobile production controls is fueling the demand for industrial printers.

There is an increase in the demand for desktop 3D printers in schools and universities, allowing students to incline more toward inspiring and practical 3D modeling experimentations. There is also a rise in the personal usage of desktop 3D printers being to develop sculptures, custom avatars, characters, and figurines. Availability and reduction in the price of new materials such as metals and wax are driving the market for desktop 3D printers. Laser metal deposition (LMD) expected to be the fastest growing technology in the 3D printing market during the forecast period. The benefits of LMD printing technology include reduction of material waste, tooling costs, repair of parts costly to replace, reduction in lead time, customization of parts as per customers’ requirements. LMD technology involves repairing, cladding, and producing parts. Some of the common applications of this technology include repair of mold tool surfaces, high value parts such as aero engine components and military vehicles, tipping of turbine blades with protective coatings, and surfacing of oil and gas drilling components. North America is expected to account for the largest share of the 3D printing market during the forecast period, with the U.S. being the major driver for the growth of the market. Major industrial manufacturing, aerospace & defense, and healthcare companies, located in the U.S., are increasingly using the 3D printing technology, which is leading to the growth of the 3D printing market. Continuous technological advancements and financial support from the government are also propelling the growth of the North American market for 3D printing. Several companies are adopting 3D printing not only for developing prototypes but also for manufacturing end-user products. The major players in the 3D printing market include 3D Systems Corporation (U.S.), Stratasys Ltd. (U.S. & Israel), the ExOne Company(U.S.), Voxeljet AG (Germany), Arcam Group (Sweden), SLM Solutions Group AG (Germany), EOS GmbH (Germany), EnvisionTEC GmbH (Germany), Materialise NV (Belgium), Sciaky Inc. (U.S.), Concept Laser GmbH (Germany), Autodesk, Inc. (U.S.), Hoganas AB (Sweden), Renishaw PLC. (U.K.).

According to International Data Corporation (IDC), the 3D printing industry is going to be rapidly expanding in the next three years. The global market intelligence and advisory services provider is predicting that 3D printing will expand globally at a 27% CAGR. IDC says that the nearly US$11 bln industry in 2015 will balloon to US$26.7 bln by 2019. This is one of the fastest rates of growth yet predicted for 3D printing, where it is expected that the West European, Asian and United States markets will primarily drive the growth. “3D printing has been a mainstay in specialized discrete manufacturing markets like automotive and aerospace for many years. However, in just the past three years, lower-priced 3D printers and affordable materials have dramatically widened the market for 3D printing to now enable consumer, education, healthcare and additional manufacturing markets. That said, 3D printing availability doesn’t translate similarly across industries. Vendors and service providers need to understand how differences in use cases, materials cost, and end customer expectation are uniquely shaping each market,” explained Vice President of IDC’s Consumer Insights and Analysis Group Christopher Chute.

The IDC guide suggests that the expected high rate of growth and expansion will be driven primarily by a few select industries rather than a cumulative effect over the entire industry. Specifically businesses that previously sold and manufactured mass-produced products will now be capable of attainable customization that will greater service individual needs and requirements. While overall the United States, Western Europe and Asia will be responsible for most of the industry growth, the IDC expects that 3D printing will continue to develop rapidly in several emerging markets throughout the world. The aggregate share of global 3D printing spending by the United States, West European and Asian markets is expected to rise from the 59.2% recorded in 2014 to an estimated 70% by 2019. This will be a result of a greater adoption of 3D printing applications within the industrial sector. China in particular is expected to become a leading market for 3D printing hardware, products and services as they begin to heavily leverage their pre-existing manufacturing and distribution infrastructure.

As per Smithers Pira, global market for 3D printing is expected to reach over US$49 bln by 2025. 3D printing is set to revolutionize manufacturing processes and methodologies worldwide. The technology is capable of printing completely integrated part-combinations as a single finished product and has the capacity to print more complex designed parts than could ever be done by traditional molding processes. The overall 3D printing market consists of the combined value of 3D printers, polymer materials, parts and services. Smithers Pira estimates the value of the global 3D printing market at US$4 bln in 2014. The market is expected to increase to US$5.9 bln in 2015 and grow to US$49.1 bln by 2025, representing a CAGR of 23.7%. The market consists of two subcategories:

* Industrial markets: 3D printing users are typically large commercial enterprises

* DIY consumer markets: 3D printing users are small residential consumers or hobbyists

The study shows that in 2015, the industrial market share is expected to be about 93% of total 3D printing market value, while the industrial market share of individual printer shipments is only about 21%, with the reminder held by the DIY consumer market. Therefore, industrial markets have the largest portion of business value, while DIY consumer markets utilize the largest number of printers. Most interesting are the industrial applications, which have the greatest value potential and reside in those markets that are served by commercial enterprises and industrial manufacturing companies. The many different industrial markets are itemized by global value in Figure 1 below. The largest markets are aerospace, automotive, consumer products and the combined medical markets, according to the report. In terms of regional markets, the report shows that North America is expected to represent 40% market share in 2015, while Europe and Asia will represent 31% and 26% respectively. By 2025, regional market shares will change: North America is expected to decline in share to 34%, with Europe share remaining relatively stable at 32%, and Asia increasing share to 33%. 3D printing has come a long way over the last 10 years, but it will still require another 5 to 10 years before it is more fully accepted by the overall manufacturing sectors. The revolution is still in its infancy; even at the forecasted 2015 market value of US$5.9 bln, this only represents about 0.02% of global manufacturing value, which was about US$25 trillion in 2014. However, with a 1% share of the global manufacturing value in 2014 equating to about US$250 bln, the magnitude of the potential for 3D printing is really quite staggering. Suffice to say at this early stage of growth, the opportunity for the 3D printing industry is extremely attractive.

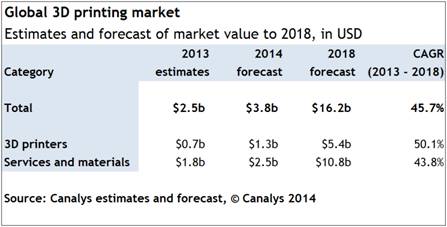

As per Canalys, 3D printing market to grow to US$16.2 bln in 2018 amid technology advances and decreasing expenses. The size of the market, including 3D printer sales, materials and associated services, is estimated to reach US$16.2 billion by 2018. This represents an expected compound annual growth rate (CAGR) of 45.7% from 2013 to 2018. “This is a market with enormous growth potential now that the main barriers to up-take are being addressed,” said Canalys Senior Analyst, Tim Shepherd. “Advances in technology are yielding faster print times and enabling objects to be printed in greater combinations of materials, colors and finishes. Crucially, prices are also falling, making the technology an increasingly feasible option for a broad variety of enterprise and consumer uses, restricted only by computer aided design competencies and printer availability – both of which are set to improve significantly. 3D printing has become an established technology for producing prototypes and concept models of all manner of products. But as it matures, there is clear and substantial potential across numerous sectors, such as engineering and architecture, aerospace and defense, and medical (particularly in the fabrication of custom prosthetics), for 3D printing to have a dramatic impact within five years.” In the short-term, Canalys expects printing-to-order services to drive considerable growth while penetration lags technology advances. “There is a clear opportunity for companies to establish 3D printing service studios to address the growing demand for the custom products that this technology makes possible,” said Research Analyst, Joe Kempton. “That demand will continue to grow, driven by three main factors: customization potential, convenience and manufacturing efficiencies. Items can be printed and personalized to order. They can often be printed locally, rather than necessitating designs be sent off to large, sometimes distant, manufacturing facilities. 3D printing also promises less material waste and often lower energy consumption than conventional manufacturing processes. Given these benefits and the breadth of use cases, there is no doubt that this market is set for robust and significant growth.” The value of the 3D printer market itself grew 109% in 2013 to US$711 mln and is forecast to grow 79% in 2014 to hit US$1.3 bln. The market value is expected to grow to US$5.4 bln by 2018. Value growth will reflect increasing commercial printer volumes and, as such, also drive growth in the volume and value of consumables shipments, including both resistant printing materials and removable or dissolvable support materials. “We are at the inflection point for 3D printing. It has now moved from a new and much-hyped, but largely unproven, manufacturing process to a technology with the ability to produce real, innovative, complex and robust products,” said Shepherd. “This is a fast-evolving market, but it is still in its infancy. Expect to see new major entrants making a significant impact in the industry in the coming years, including giants such as HP. As barriers fall, new use cases emerge, the technology improves and new entrants join, this is a market that will look very different in five years’ time.”

|

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}