| The essential ingredients in a PVC formulation are: • PVC Resin o Suspension Grade o Paste Grade o Copolymer • Primary Plasticiser • Secondary Plasticiser • Stabilisers o Heat Stabilisers o Light Stabilisers • Lubricants • Fillers • Pigments • Special Additives PVC Resin There are 4 types of PVC Resin grouped by polymerization method 1. Suspension Grade PVC 2. Emulsion Grade PVC 3. Bulk Polymerised PVC 4. Copolymer PVC Suspension Grade PVC: The most widely prevalent type, Suspension grade PVC is made by polymerizing droplets of Vinyl Chloride monomer suspended in water. When Polymerisation is complete, the slurry is centrifuged and the PVC cake is gently dried by special heating systems so as not to subject the unstabilised resin to heat degradation. Particle size of the resin ranges from 50-250 microns and have porous popcorn like structures which readily absorbs Plasticisers. The structure of the PVC particles can be modified by selecting suitable suspending agents and Polymerisation Catalyst. Less porous types are extensively used for the high volume Rigid or Unplasticised PVC applications like PVC Pipes, Windows, Sidings, Ductings. Suspension grades of a coarser particle size and very porous structures absorb large quantities of Plasticiser forming a dryblend at temperatures as low as 80oC.The more porous types are used in Plasticised applications like Cables, Footwear, Soft Calendered Sheeting and Films etc. Emulsion Grade PVC: Emulsion Polymerised PVC is what Paste Grade Resin is and this is almost exclusively used for Plastisols. Paste grade resin is a very fine particle size PVC produced by spray drying an Emulsion of PVC in Water very much like how milk powder is produced. Paste grade resin needs much more energy to produce and is considerably costlier than Suspension resin. The paste grade resin carries the emulsifying chemicals and catalysts with it. It is therefore less pure than Suspension Polymerized or Bulk Polymerized PVC. The Electrical properties of Paste grade resin plastisols are therefore much poorer than Suspension Resin Compounds. Clarity is poorer than Suspension or Bulk PVC. Paste grade resin is compact in structure, and does not absorb much Plasticiser at room temperatures. Temperatures in excess of 160-180oC are needed to drive the plasticer into the Resin during curing. Paste grade Resin is extensively used for Cushion Vinyl Floorings of wide widths. Different layers of specially formulated pastes are coated either on a suitable substrate (Direct Coating) or on Release Paper (Transfer coating). The layers are fused continuously in long ovens and rolled up after release paper is stripped off. The rolled good flooring can have a tough semitransparent wear layer over printed and foamed layers which are sitting on top of highly filled base coats to build up the thickness. Many extremely attractive and rich effects are possible and these represent the higher end of Vinyl Flooring. Bulk Polymerised PVC: Bulk Polymerisation gives the purest form of PVC resin as no emulsifying or suspending agents are used. They are mainly used in transparent applications. They are mainly made available in the lower K value groups, as Unplasticised PVC Foils for Blister Packaging and other Calendered/Extruded Transparent films are best processed from lower K Value grades. Refinements in Suspension resin technology has edged out Bulk PVC in the recent past. Copolymer PVC: Vinyl Chloride is copolymerized with comonomers like Vinyl acetate give a range of resins with unique properties. PVAc or Copolymer of Vinyl Chloride and Vinyl acetate is the most important. The good solubility in solvents of PVAc makes it the prime choice for Vinyl Printing Inks and solvent cements. There is a very special application of PVAc in Floor tiling and it is the resin of choice for Vinyl Asbestos tiles. The Resin is actually a binder rather than the main ingredient. With Copolymer Resin it is possible to manufacture floor tiles with Fillers like Asbestos and Calcium Carbonate accounting for as much as 84% with the Copolymer and other compounding additives as low as 16%. Such high levels are not possible with Suspension resin as its melt viscosity is much higher and cannot coat and encapsulate such high levels of inert filler. Special callendering trains are required for Vinyl asbestos tiles. However with Asbestos falling out favour, such products have slowly died out. K Value PVC Resins are classified by their K-Value, an indicator of the molecular weight and degree of polymerization. • K70-75 are high K value resins which gives best mechanical properties but are more difficult to process. They need more plasticizer for same softness. High performance Cable insulations in Suspension resin and tough coatings for Conveyor belts, Industrial Flooring and similar high end applications in Paste grade are some popular application. It is the costliest. • K65-68 are medium K value resin which are the most popular. They have a good balance of Mechanical properties and processibility. UPVC (Unplasticised or Rigid PVC) is made from the less porous grades while Plasticised Applications are best made from the more porous grades. There is a lot of grade choice as they cater to the Majority of PVC applications. Because of its sheer volume this family of PVC resins are priced the lowest. • K58-60 are low K-value ranges. Mechanical properties are lowest, but processing is easiest. Many difficult to process applications like injection moulding, blow moulding and Clear Calendered packaging film are made from the lower K value ranges. Prices are higher than Medium K Value Resins. • K50-55 are special resins which are tailor made for some demanding applications. Interesting ones are Battery Separator Resins and Blending resins used along withPaste Grade resin to reduce costs. Processing is easiest. As PVC is 56% Chlorine, it is one of the few Polymers which are self extinguishing, as Chlorine is a strong Flame inhibitor. Primary Plasticisers: Plasticisers make the hard PVC resin softer. Primary plasticizers have good compatibility with PVC resin and can be absorbed in large quantities. In special cases as much as 140-150 PHR of Primary plasticiser can be gelated into PVC for super soft products. Nearly all Plasticisers are liquids and have to be absorbed in Suspension resin in heated mixers. High Speed mixers (which generate frictional heat while mixing) are the most popular types of dryblending equipment. Heated Ribbon blenders and Sigma mixers are only used when very high Plasticiser levels are required. There is a vast array of Primary plasticizers for PVC. This discussion will be limited to the most popular, the Phthalate Esters. Phthalic acid is reacted with various alchohols to manufacture a family of Phthalate plasticizers of which Di Octyl Pthalate (DOP) is the most popular. Other important Primary Plasticisers are DOA & DOS (for low temperature applications), Trimellitates (for high temperature applications and Polymeric Plasticisers (High permanence). The number of Carbon atoms in the Alcohol decides the gradation of Properties

The higher Carbon atoms Phthalates have better permanence. They do not volatilize easily at high temperatures. If a Plasticiser volatilizes the product becomes harder and brittle. Fusing and gelation take longer with DNP & DIDP. Phthalate Plasticisers are not fire resistant. They are the main reason why Flexible PVC products are much more flammable than Unplasticised (Rigid) PVC. There are flame resistant Plasticisers, mainly Phosphates but they have to be imported. There are many more families of Plasticisers for special properties, (Low Temperature, High Permanence, Non Migrating, Continuous High Temperature, Smoke resistance etc etc.). One important concept has to be understood: Plasticising Efficiency. The Plasticising efficiency of DOP (the most popular) is set as 1. The Plasticising efficiency of any other plasticizer is expressed as a ratio with DOP for producing a moulding of same softness. For example if 50 PHR of DOP yields a Shore hardness of 77, and 55 PHR of another plasticizer gives the same hardness, the Plasticizing efficiency of the plasticizer is 50/55 x 100 or 0.91 (91%). For example for the Phthalates discussed above, the Plasticising efficiencies are:

This concept is very important for the next group discussed. Secondary Plasticisers: Secondary Plasticisers and extenders have limited compatibility. Their main purpose is to decrease costs. Some properties like fire retandance are improved. The most common Secondary Plasticisers are the Chlorinated Paraffins. Waxes or Paraffin oils are chlorinated, Chlorine level varying from 40-60%. Chlorinated Paraffin Waxes (CPW) are very viscous and rarely used nowadays. Chlorinated Paraffin Oils (CPO) is much more popular as the Viscosity and Plasticising efficiency is better than CPW. The higher the Chlorine Content the better the Plasticising Efficiency, but Viscosity is higher. Addition of CPO adversely affects Gelation rates. Cost increases as Chlorine levels increase. Special Paraffin Oil cuts are also used as extenders but are overshadowed by their Chlorinated derivatives. Another important parameter is Compatibility. This determines how much Secondary Plasticisers PVC can hold. If addition levels exceed the Compatibility limit, the secondary Plasticiser will ooze out on the surface of the product during use. Secondary Plasticisers are rarely used as sole Plasticiser except in Semi Rigid applications. Primary Plasticisers have to be included in the recipe for Secondary Plasticisers to be of any use.

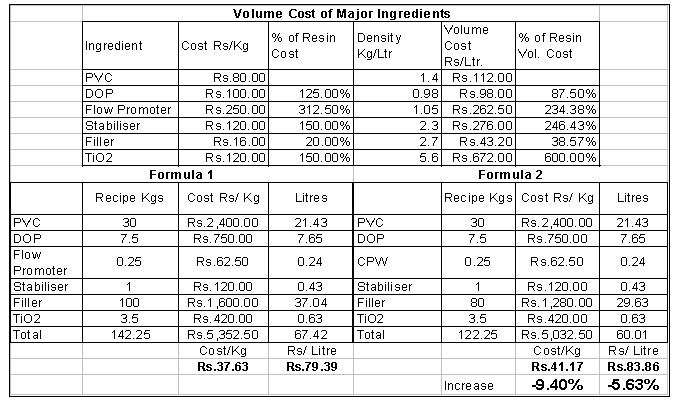

Stabilisers: The PVC molecule is unstable to heat and light. Heating PVC causes breakage of the Polymer chains, liberating Hydrochloric Acid gas. The HCl catalyses more degradation and the degradation can become explosive, releasing large quantities of corrosive HCl and other toxic gases. Exposure to Ultraviolet Radiation also breaks up Polymer chains, but is much slower than Heat degradation. Heat Stabilisers: To process PVC it has to be stabilised against the action of Heat required at processing temperatures. A majority of Stabilisers contain metal elements which react with HCl and inhibit further degradation. They are Metal Salts, Soaps or Complexes. Stabilisation of PVC is a vast subject and these are the second most important ingredient after Plasticisers in a Flexible PVC formulation. Some of the most important families are:

Many of the Mixed Metal Stabilisers also protect PVC from UV radiation attack. Among the Lead Stabilisers, DBLPhosphite has some UV resistance properties.However their light stabilization effect may need to be boosted in application subject to outdoor exposure to harsh conditions. Such light stabilisers are complex chemicals like HALS and are very expensive (Rs. 3000-5000/kg). While they are effective at very low dosages (0.1-0.3 PHR) they are only used if absolutely necessary due to their high cost. An important group is the Epoxidised Vegetable Oils mentioned under Secondary Plasticisers. These boost the Heat and Light stabilizing effect of many Stabilisers. Commonly referred as the Synergistic effect, they are frequently used in combination with mixed metals for best results. The most popular are Epoxidised Groundnut Oil and Epoxidised Soya Bean Oil. Lubricants: Lubricants prevent hot PVC from sticking to metal surfaces while processing. They are a must with suspension resin compounds but have a much lesser role in Plastisol. Stearic Acid, Waxes including High Molecular waxes and many complex esters are commonly used. Dosage are low, 0.1-0.3 PHR. Lubricants and their correct selection plays a vital role in processing. Too little and the melt is sticky, hangs up inside processing surface and starts degrading. Too much, and the melt slips on the extruder screw, reducing production rate. Overlubrication inhibits gelation and prevents full physical properties to develop. Metallic Soaps like Lead Stearate, Calcium Stearate etc have stabilizing as well as lubricating action. Nearly all of the Mixed Metal and Tin Stabilisers are non lubricating. Lubricants can be Internal (Lubricating the movement of melt molecules, improving processability) and External (Lubricationg melt flow over metal processing surfaces). The Lubrication system has to have a balance of both. Fillers: Fillers are inert inorganic powders whose major role is to reduce costs. Additions of fillers, especially in high dosages, adversely affect most desirable properties, and therefore are rightly viewed as cheapening agents. But some properties like Electrical strength and stiffness can improve. Reinforcing fillers like Glass Fibre, Carbon Fibre will not be discussed here. They are much more expensive than PVC resin and not widely used in PVC formulations. Non Reinforcing Fillers are a wide ranging group. For PVC the most important is Calcium Carbonate. There are two types of Calcium Carbonate which are widely used: Ground Calcium Carbonate: Good quality Limestone (Whiting) mined from the quarries is pulverized into powder of a particle size suitable for addition in plastics. This is by far the cheapest type of filler, with transportation costs sometimes exceeding the product price. Purity of ground calcium Carbonate depends solely on the quality of the Limestone source as there is no chemical refining process to remove impurities, especially abrasive silicate and other rocky materials. Ground Calcium Carbonate is extensively used by Leather Cloth Manufacturers who coat a PVC Paste on to substrates like Textiles, Paper etc, which is then cured continuously in an oven. The abrasive contaminants can be handled by the knife coating process. The abrasive nature of Ground Calcium Carbonate prevents its widespread use with Suspension Resin as the abrasion on extruders and Injection Moulding machines would be prohibitive. Coated fabrics made with the much costlier Paste grade resin is able to compete with Laminated products made from Suspension Resin because of the cheap filler used. Not all Ground Calcium Carbonate is of low quality. Premium Champagne whiting from special Limestone quarries can be more expensive than PCC and is used in high end Electrical and Pipe applications. These are imported. The surface quality is badly affected by ground Calcium Carbonate, but in Leather Cloth industry normally a thin high quality top coat which hides these defects. Its effect on Plastisols for Dip mouldings could be evaluated. Precipitated Calcium Carbonate: Limestone is dissolved and impurities filtered out. After further chemical purification to remove Iron and Magnesium, the solution is carbonated with CO2. Very pure Calcium Carbonate is precipitated and this is filtered and dried.. There are several grades depending on purity and particle size. Prices vary according to grade. Precipitated Calcium Carbonate (PCC) is the most widely used filler in PVC. PCC, by the way, is the main ingredient in toothpaste which accounts for much more tonnage that PVC Fillers. There are therefore many manufacturers in India. Both Ground and Precipitated CaCO3 absorb expensive Plasticisers, taking away some portion meant for flexibilising PVC. Thus more DOP has to be added to compensate, thus partly offsetting cost advantage. This can be significant especially as doses go up. Viscosity also increases. To reduce the Oil (DOP) absorption Precipitated Calcium Carbonate is coated with Stearic Acid / Calcium Stearate. DOP absorption is reduced considerably and processing and gloss improves. These are premium fillers and are termed Activated PCC. Recently, better quality GCC are being offered by several manufacturers and are replacing the costlier PCC in lower end PVC applications like Agri Pipes, SWR etc. Other mineral fillers are Talc, Dolomite, Wolastonite and Asbestos. Asbestos was widely used in Vinyl Floor tiling but its carcinogenic nature has prevented its use nowadays. While Calcium Carbonate seems to be the most attractive cost reducing agent, care has to be taken in optimizing its addition level and grade selection for best results. The concept of Volume cost will be taken up in the last section. Pigments: Pigments again are a vast subject. They can be broadly classified as: � Inorganic Pigments � Organic Pigments � Carbon Blacks. Inorganic pigments are oxides and salts of metals as well ass complex minerals. The most important is Titanium Dioxide which is the chief whitening pigment used in Plastics. Important Inorganic Pigment groups: � Ultramarine: Blues and Violets � Chromes: Yellows, Orange, Brown � Cadmiums: Reds, Orange, Yellow � Iron Oxide: Brow, Black. Iron oxide tends to catalyse decomposition of PVC so must be used wit care if at all. Inorganic pigments are heat stable, cheaper but does not have the colour strength and brightnes when compared to organic pigments. Important Organic Pigment Groups: � Phthalocyanines: Blue, Green � Chromophthals: Red, Orange � Azos: Wide range of colours, but carcinogenic. � Lakes and Toners: Oil soluble dyes leach out with the plasticizer in PVC. However when deposited and reacted with inorganic carriers, they for Lakes which are widely used in Plastics Masterbatches: The modern trend is to depend on masterbatch suppliers to provide the technology of obtaining the right shade in the product. Developing colours in-house starting with pigments is a complex job. Maintaining shades requires very accurate weighments of multiple pigments. Though it is the cheapest route, the conveniences of masterbatches make it the preferred colouring route. A masterbatch is a colour matched pigment mixture dispersed and encapsulated in a Polymer carrier which is compatible with the Polymer being processed. Special Additives: There are a wide variety of special additives which can be added to improve performance of the moulding. These will be discussed in detail at a later time, but the most interesting are listed: Flow Promoters: Special Acrylic Polymers aids in the processing of PVC by reducing the melt viscosity. They are mainly used in Rigid PVC applications which are difficult to process like Pipe Fittings, Calendered and Extruded Sheet and thick wall Pipes. They have limited effectiveness in Plasticised PVC, but are used in some applications where Plasticiser level is low. Impact Modifiers: A family of Acrylic and MBS copolymers, they act like rubber and improve resistance to shock loads in Rigid PVC products. CPE (Chlorinated Polyethylene) is widely used as an Impact modifier in PVC Pipe. Fire Retardants and Smoke Suppressants: The classic route of imparting Fire and flame retardancy to Plastics is well established. Most polymers can be burnt quite easily. By introducing a Halogenated compound and then adding Sb2O3 the polymer gets protected from burning. The Halogen reacts with the Antimony trioxide emitting a thick cloud of non burning gas which envelopes the burning part like a blanket. Oxygen supply is cut off and the flame extinguishes. • Fortunately PVC already is 56% Chlorine, a Halogen. Thus costly (and Toxic) Brominated compounds need not be added as is the case with other polymers. Addition of Sb2O3 need not be as high as in other polymers • ATH is a chemical which contains water of crystallization. It can be added as filler. When a flame strikes the product, ATH releases steam which acts as a fire extinguisher and counteracts the flame. • There are many other proprietary Flame retardant and Smoke suppressing additives, most of which are imported. Foaming Agents: • Foaming Agents are chemicals which decompose at gelling temperatures giving off inert gases like Nitrogen or Carbon Dioxide. The gases are trapped on the thick melt and generate a foamed structure. • This is a useful way of increasing the bulk or volume of the moulding and lowering the density considerably. They are extensively used in the Leather cloth industry and another well known application is microcellular shoe soles. • Many novel embossed an raised effects are obtained in spread coated Vinyl Rolled good flooring by printing patterns with PVC Plastisols containing blowing agents. On curing the printed portions foam up and give novel patterns. Fungicides and Biocides: • Protects the non plastic components like Plasticisers from mould growth. This is especially important in wet and humid environments like Bathrooms. PVC Shower curtains often need such protection. Volume Cost: Volume cost and its implications are not properly understood by many entrepreneurs. It is vital to understand its implications before embarking on cost reduction exercises. Plastic finished goods are rarely sold by weight. They are priced either per piece (Mouldings) or per unit length (Pipes, Cables, Tape). Thus the costing and pricing are for fixed Volumes. As the Plastic Raw materials are always purchased per unit weight, the tendency is to do cost calculations on a Per Kilo basis, and the finished product is priced accordingly. If cost calculations are done on Per Kilo basis, many times the reduction in cost by adding fillers is calculated as a percentage of original formulation cost. The savings may be translated into a price reduction, especially in competitive situations to maintain market share. After some time the entrepreneur realizes that he is sustaining losses as the reduction in Volume cost was nowhere near the Per kg. cost reduction. Volume cost (Rs./Litre)= Purchase Cost (Rs./Kg.) x Density (Kg./Litre or gm/cc) In your Floor tile formulation, the filler loading is very high. Many problems could be solved by reducing the filler loading. However this may be thought to be the last resort as costs would go up. If viewed from a volume cost angle, the increase in actual cost is not that high. If rejections and scrap generation drastically reduce, reducing Fillers may prove cost effective. In the following example, a 20% reduction in filler would appear to increase the cost on a per Kg. basis by about 9.5%. On the basis of Volume cost, the increase is actually 5.6%. If reduction of wastage and rejects improves by about 5%, the proposed reduction in Filler would be cost efficient.  (Author: Mr. Siddhartha Roy, Consultant, Roy PlasTech)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Previous Article

Next Article

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}