|

Airbus 380: an engineering marvel

Airbus recently developed the World’s

largest airplane Airbus 380, capable of carrying

800 passengers- twice the capacity (of only

400 passengers) as compared to the present largest

plane. The weight of the plane was a very major

constraint while designing this gigantic plane,

limiting concepts.

The problem of excessive weight for an airplane

of such gigantic proportions was resolved due

to the development of very large Carbon fiber

composites. Carbon fiber composites are the

same composites commonly used for tennis racquets.

Such composites were so far available only in

smaller sizes. The challenge to the Airbus designers

was to develop very large size composites. This

gigantic 7 story tall plane weighs barely 500

tons, as composites are used to knock 1.5 tons

off the weight of the airplane's center wing

box alone, an essential structure that binds

the wings to the fuselage.

Compared to the Aluminum generally used in

airplanes, these composites offer following

advantages:

|

|

Better stiffness

compared to Aluminum |

|

|

No corrosion |

|

|

Ability to withstand higher

pressures |

|

|

Ability to withstand

frequent cycle of pressurizing and depressurizing |

|

|

Ability to provide larger

windows |

|

|

Ability to withstand higher

humidity level that provide better comforts

to the passengers |

To achieve composites of such large sizes, cost

was a major hindrance. More than 30 global vendors

- manufacturers of composites, developed an economic

way of making large sized composites. This was

possible only by seeking developmental help from

the processors situated geographically away from

France, (the headquarters of Airbus) where the

development of this new airplane was undertaken.

In fact, Boeing has been using large sized

composites in military planes. However, the

higher costs of these military planes can absorb

excessively higher cost. Airbus demonstrated

that these composites can be developed at a

lower cost for passenger planes.

Previous Article

Next Article

Tell Us What You Want

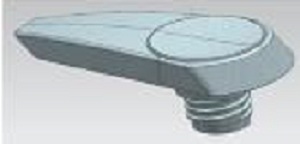

Moulds for lotion pump

| | | |