|

Stabilisers:

The PVC molecule is unstable to heat and light. Heating PVC causes breakage of the Polymer chains, liberating Hydrochloric Acid gas. The HCl catalyses more degradation and the degradation can become explosive, releasing large quantities of corrosive HCl and other toxic gases. Exposure to Ultraviolet Radiation also breaks up Polymer chains but is much slower than Heat degradation. Heat Stabilisers: To process PVC, it has to be stabilised against the action of Heat required at processing temperatures. Most Stabilisers contain metal elements which react with HCl and inhibit further degradation. They are Metal Salts, Soaps or Complexes. Stabilisation of PVC is a vast subject, and they are the second most important ingredient in UPVC Formulations and after Plasticisers in a Flexible PVC formulation. Some of the most important families are: |

| Type | Form | PHR used | Clarity | Toxicity | Odour | Cost/Kg |

|---|---|---|---|---|---|---|

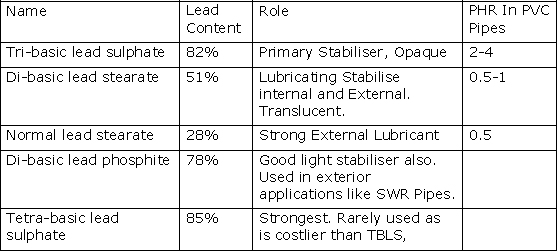

| Leads | Powder | 2 -4 | Opaque | Toxic | None | ~ Rs 120-150 |

| Ba- Cd | Liquid | 1.5 – 2.5 | Clear | Very Toxic | Slight | ~ Rs 200 |

| Ba - Zn | Liquid | 2 - 3 | Clear | Toxic | Slight | ~ Rs 190 |

| Cd - Zn | Liquid | 2 - 3 | Clear | Toxic | Slight | ~ Rs 220 |

| Ca - Zn | Liquid | 3 -4 | Clear | Non-Toxic | Negl. | ~ Rs 250 |

| Tins | Liquid | 0.5 -1 | Crystal | T & Non | Strong | ~ Rs 350 |

| Ba - Zn | Liquid | 2 - 3 | Clear | Toxic | Slight | ~ Rs 190 |

| Type | Heat Stability | Main Applications | Not recommended for |

|---|---|---|---|

| Leads | Very Good, esp. long term. | Cables, Pipes & Fittings, Sleeves, Profiles. Cheapest. | Clear Application. Can be toxic. |

| Tins | Best | Transparent tubings and sheeting, High quality Pipes, Medical | Causes sulphide staining with Leads. Costliest Stabiliser. |

| Cd - Zn | Moderate | ROHS Cables, Non-Toxic. Pipes and Extrusions. | For high heat history. |

| Ba- Cd | Good | Leather Cloth, Calendared products, Footwear. | Non Toxic applications |

| Cd - Zn | Moderate | Foamed Leather Cloth | For high heat history. |

| Metallic Stearates | Low | Co-stabilisers with lubricating action | Sole Stabiliser. |

| Siddhartha Roy | ||

|

Previous Article

Next Article

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}