|

PVC certainly is one of the most versatile

plastics even though it has lost its premier

position to PP in the nineties. PVC is still

consumed at about 30 million tons out of the

total of 165 million tons in 2003. PVC therefore

has almost 20% share of the global plastic consumption.

While polyolefins are the first material of

choice for packaging, PVC still continues to

be the major building block for construction

application segment.

PVC enjoys practically 2/3rd share of the pipe

and wire/cable applications. Both these applications

are characterized by their usage for quite a

long time. Both pipes and wire/cable have normally

more than 25 years of safe usage. PVC therefore

does not surface in the waste/recycling as much

as polyolefins. Another interesting aspect of

PVC is that it has possibly the widest range

of processing techniques compared to all other

polymers. Calendering as well as paste techniques

like spread coating, slush moulding and dip

moulding are predominantly used for PVC. What

is most remarkable that the applications of

PVC cover a very broad spectrum of products

that have either very high flexural modulus

(such as pipe or building profile) or high flexibility

(such as footwear or refrigerator liners or

several soft gaskets/profiles).

There are essentially four polymerization techniques

that are used for manufacture of PVC polymer,

but suspension is by far the largest process

that is employed. Suspension process accounts

for about 90% of the global production of 30

million tons. Emulsion and mass processes although

provide some specific advantages to PVC are

growing at almost half the rate compared to

suspension polymer. Solution process has a very

small role to play for coating application.

PVC homopolymer has the largest market share and possibly accounts for almost 95% of the global PVC. There are many copolymers or specialties but are almost losing their share.

PVC is predominantly an amorphous material

because of its predominant stactic structure.

However it can contain about 5-10% of crystalline

particles due to the presence of syndiotactic

structure. Higher molecular weights can contain

higher level of crystalline particles compared

to lower molecular weight. This crystalline

phase can affect the properties of PVC product

that contains lower level of plasticizer. In

fact, those PVC products having Shore hardness

beyond 97 and Shore D hardness between 30-40

are quite prone to the effect of the crystallinity.

The mechanical properties of such products could

have very wide variations due to different levels

of crystallinity.

Molecular weight is defined by primarily 3 different

values. They are :

(1) K value (2) Relative/Inherent viscosity

or viscosity number (3) Mean polymerization

degree.

The correlation between these three properties

and molecular weights are given in Table 1.

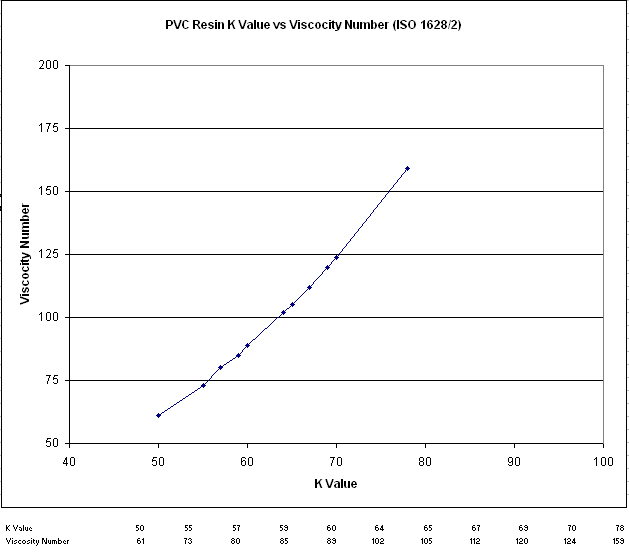

Figure 1 shows the relationship between K value

and Viscosity Number.

Medium molecular weight ranging from K value of

60-67 is more widely used compared to low molecular

as well as high molecular weights. Low molecular

weight polymer grades are used for rigid products

while very high molecular weight grades are

used to obtain special properties like matt

surface finish or better toughness. Commercially

low molecular weights are available with K values

in the range of 45-50 and extra high molecular

weights have K values in the range of 80-104.

However, the commercial usage of both these

grades is only in niche products and therefore

they have a share of less than 5%.

Molecular weight distribution in PVC is in a narrow range of 2-4 and has possibly much less pronounced effect on the processing as well as performance of PVC products.

Compared to the effects of structure of PVC,

its particle morphology plays an important role

in processing and performance of products. The

emulsion grades designed for spread coating

have the most narrow particle size (4 micron)

while the pipe grade suspension grade has the

coarsest particle size, since pipe is processed

from dry blend. The particles are tuned finer

or coarser according to the applications. For

instance clear rigid PVC products like film

or bottle have finer particle size range to

achieve excellent dispersion of additives and

attain clarity. Besides, the morphology of particles

plays an important role. For instance, the emulsion

grade polymer has solid spherical particles

with in a narrow particle range. Addition of

plasticizers to such polymer results into a

formation of paste. On the other hand the particles

for wire/cable as well as plasticized clear

products require uniformly hollow particles

to achieve excellent plasticizer dispersion.

In fact the uniform porosity is a prime requirement

of all plasticized applications. The particles

of spherical nature provide ease of dispersion

of additives. Bulk density of PVC polymer is

an important characteristic that helps in its

selection for different applications. For instance

polymer grades ideally suited for plasticized

applications have bulk density on a lower side

(less than 0.53) while grades for pipes have

bulk density on a higher side (> 0.56).

Fish eyes are quite commonly observed in PVC polymer

because of presence of gel (higher molecular

weights). These are objectionable and cannot

be acceptable for specific applications such

as thin wire or clear film/bottle. These fish

eyes are controlled during polymerization and

good manufacturing practice help in achieving

“fish eye” free grades. It is therefore

advisable that the processors of good quality

clear products or wire products screen PVC batches

for fish eye rating by conducting film-blowing

test.

The purity of PVC polymer not only affects the

clarity or creates fish eyes but also cause

deterioration of electrical properties. For

such critical applications it is important to

regularly conduct quality control test on the

incoming PVC for purity. One of the simple tests

used for wire/cable is determination of conductivity

of water extract. This value signifies the impurity

of material that is soluble in water.

PVC is typically manufactured with water as

a heat dissipation medium. The resultant PVC

polymer tends to have some residual water/moisture

that has not got evaporated even after drying.

During storage PVC tends to absorb some more

moisture. Higher level of moisture (more than

0.3%) interferes with performance of finished

product. It is essential that more care be taken

to prevent ingress of moisture during storage

particularly in humid condition.

PVC is generally produced either by batch process or by semi continuous process. It is therefore quite difficult to achieve very uniform properties in every batch. For achieving more uniform properties of finished product, it is necessary not to mix more than one batch. The batch segregation would result into better products.

The selection of PVC polymer grade is very

important for different products. The wrong

usage of PVC grade calls for doom. It is very

important that processors always select the

correct grade for application.

This article focuses on the characteristics

of PVC polymer for more sensitive end products.

PVC polymer manufacturers can provide more guidance.

The environmental issues have caused concerns on growth of PVC over the last three decades. The scientists and researchers involved in PVC always have come up to resolve these problems regularly. PVC therefore continues to grow at least at the global GDP growth of about 2.5-3%. It is expected that it will continue to do so even when the overall polymer would grow at about 5-6%

|