|

There are a few plastics such as PVC or

ABS that have inherent tendency to turn yellowish or get discoloured

during the process of manufacturing, making the polymers look very

dirty. To avoid or prevent the yellowish dirty look, optical brighteners

are used alone or in combination with other dyes to produce pleasing

color shades. Generally pastel dyes are used because they give a

cleaner and brilliant appearance. Additionally, these optical brighteners,

which are essentially fluorescent whitening agents, are always used

while restoring recycled plastics. These optical brighteners function

by absorbing light in UV-A range (320-400) and re-emitting the light

in the visible blue range (400-480). During the emission they provide

fluorescence. Optical brighteners are more effective in lighter

shades and may not be very useful in the dark colours.

Two of the most commonly used optical brighteners are derivatives

of the bis-benzoxazoles (bis-benzoxazolyl-stilbene (BBS) and bis-benzoxazolyl-thiophene

(BBT). Both of these products have a very high melting point as

well as excellent thermal stability. While BBS can be used for all

plastics except PVC because of their low compatibility, BBT is used

for PVC. These optical brighteners are generally very expensive

but are required to be used at very low levels. The typical dosage

could be as low as 5-10 ppms for natural polymers and about 250

ppms for coloured polymers. Both of them can be used in contact

with food. The polymer manufacturers can incorporate them during

manufacturing process. However, masterbatches of optical brighteners

are also available from major suppliers for the converters. For

PVC, optical brightener can be used during compounding process.

Previous Article

Next Article

Tell Us What You Want

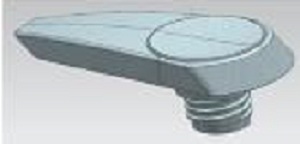

Moulds for lotion pump

| | | |