|

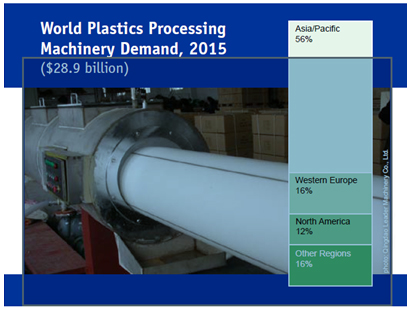

Global demand for plastics processing machinery is projected to rise 6% pa through 2015 to US$28.9 bln, a rebound from market declines experienced during the recession impacted 2005-2010 period, as per Freedonia. Sales growth will be driven by an acceleration in plastic product manufacturing, as well as by a favorable fixed investment environment worldwide. Many nations are building up their plastics manufacturing infrastructure, due to both rising domestic demand for plastics-consuming goods and export opportunities to developed nations. Plastics processing machinery production will grow the fastest in the Asia Pacific region through 2015, expanding 7.7% pa. Gains in developing nations will be the driving force behind advances in the global market for plastics processing equipment. China, for example, will account for over 40% of all additional global demand through 2015, with growth stimulated by strong increases in plastic manufacturing as industrialization efforts continue and income levels rise. Other nations in Asia with smaller, less-developed economies, such as India, Vietnam and Thailand, will also record healthy market gains. In developed areas of the world, most notably the US, Western Europe and Japan, demand will rebound after a period of decline, although sales advances will not be as strong as those in developing nations. Among major product types, extrusion equipment will post the strongest gains through 2015, benefiting from growth in global construction spending, that will fuel demand for extruded goods like pipe and siding. Injection molding equipment will remain the largest product segment, accounting for 40% of demand in 2015. Injection molding machines are used in a wide array of applications, ranging from automotive components to consumer goods to medical supplies. The construction market will post the strongest gains through 2015, benefiting from an acceleration in global construction spending. The consumer/institutional products market will also post solid gains, reflecting rising standards of living. The packaging market will post respectable gains due to rising manufacturing output and consumer demand for packaged products. In addition, plastics will continue to gain market share from other materials in applications such as bottles. |

|

| As per Global Industry Analysts, global plastics processing machinery market plummeted in 2008-2010, as the global economy experienced the worst recession since the Great Depression of the 1930s. The industrial sector has been one of the worst affected segments of the global economy. However, significant variations were evident across various regional markets. The recession-induced decline hastened the global shift in plastics processing machinery manufacturing from the West to the East. As a result, emerging markets of Brazil, China, India and Russia are becoming significant contributors to sales volume and manufacturer revenues. China replaced Germany as the leading producer of plastics processing machinery in 2009 owing to the significantly low contraction in China as compared to Germany. The recession also fostered the industry’s shift towards complete production systems and highly automated investments, specifically in the emerging markets where companies have less-developed internal development capabilities. Weak demand in domestic markets compelled manufacturers to look at other international markets to try and offset losses, which intensified price-based competition among them. With significant reduction in profits, most of the leading end-users reduced capital expenditure on the processing machinery during the recession-struck period. However, the market for plastics processing machinery moved up the recovery ladder rather quickly once the global economies set into a phase of recovery. Ease of manufacturing and versatility have transformed plastic into one of most essential materials in consumer as well as industrial products. Plastics has grown into one of the most promising and rapidly growing industries worldwide since the 1950s, fast replacing other material types including glass, wood, paper, metal etc., in a variety of applications. Plastics are increasingly being used in sectors such as automotive, construction, medical, packaging, agriculture, electrical and electronics, houseware, and pharmaceuticals. This contributes to demand creation for huge precision plastics processing machines and plastic molding equipment to manufacture flawless plastics products. The top application areas of plastics include packaging, construction, and automotive. Improving demand for plastics has resulted in tremendous ascends in the capacity usage of the processing sector and this trend is likely to carry on. Construction products, automotive parts, and packaging are the three major application areas for plastics particularly in the developing nations. The other potential growth sectors include electronics, information technology, and health sector. Plastics processing machinery is a high technology and dynamic market. Production efficiency of the major plastics processing technologies has almost doubled in the last 20 years, while energy consumption is said to have declined by 30% mainly because of the technological advancements the industry witnessed over the years. Machines costing millions and possessing sophisticated functionalities are used in producing single plastic containers. Machines that were considered modern and hi-tech a decade ago are not the same workhorses on production floor today. Equipment must be useful and possess practical capabilities such as high speed, efficiency, and low maintenance with intricate decorating capabilities. The technical superiority of the plastics processing machines is getting better with every passing generation. Today, machines are being manufactured with shorter life spans and with the current pace of technical advancements. Application areas for plastics are enhanced when new products are developed or invented in sports, recreation, and medical care sectors. New inventions use high value technological plastics such as bio assimilating plastic prosthesis, which finds use in the medical sector. As stated by the market research report on Plastics Processing Machinery, Asia-Pacific is the largest regional market worldwide in terms of value. Asia-Pacific also emerges as the fastest growing regional market surging ahead at a compounded annual rate of 5.4% over the analysis period. Within Asia-Pacific, China, witnessing burgeoning demand for plastics, is the fastest growing market for plastics processing machinery. The Indian plastics market holds enormous potential due to the rapid rise in consumption, especially in automobile, consumer, and transportation sectors. Taiwan is ranked among the top five global manufacturers and exporters of plastic and rubber processing machinery. Segment wise, Injection Molding Machines represent the largest as well as the fastest growing segment in the global plastics processing machinery market. Extrusion Machines and Thermoforming Machines represent the other two major plastics processing machinery categories worldwide. With plastics processing industry experiencing an increasing shift of manufacturing facilities to Eastern Europe and Asian countries, the production landscape is expected to change significantly in the years to come. Major reason behind the shift includes low-cost labor, local demand, and distribution dynamics. |

Previous Article

Next Article

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}