|

It is well known that PP manufacturers

modify flow of Polypropylene by making adjustments of molecular

weight using peroxides to breakdown molecular chains. This process,

known as "vis" breaking helps PP producers to rationalize

polymerisation operation.

Most of these peroxides are liquid and extremely

hazardous. The producers of PP have excellent safety setups capable

of handling these peroxides. However, the converters, such as producers

of PP non-wovens using melt blown process or manufacturers of large

moulded products like bumpers, etc. would find it very difficult

to handle peroxides directly on the processing equipments. These

peroxides can be developed in the diluted solid form using one of

the following methods.

Absorption in fillers:

Absorption in fillers:

Peroxides can be absorbed to almost

50% level by mineral fillers like CaCO3, chalk or sillica.

Since the amounts of peroxide required is quite small

(250-1000 ppm), the total usage of the peroxide concentrate

in fillers is quite small, making usage feasible. The

dispersion of filler in the main product would be difficult

and can cause some quality problems (for instance, in

melt blown fibers).

Absorption in Porous PP

polymer:

Absorption in Porous PP

polymer:

Spheripol process has the ability

to produce porous PP powder. Peroxides could be absorbed

in this porous PP polymer almost to the extent of 20%.

This option is more expensive than fillers, but offers

better dispersion. There are some ultraporous PE/PP/EVA

powders that can absorb more than 50% of peroxides. However

these ultra porous polymers are very expensive.

Peroxide Masterbatches:

Peroxide Masterbatches:

Peroxides have a very high flow characteristic,

can be incorporated into a polymer carrier upto 10%, hence

can be extruded/compounded at very low temperatures to

avoid decomposition. There are very few suppliers of Peroxide

Masterbatches due to a difficult manufacturing process,

causing the cost of the peroxide masterbatches to be quite

high.

However, the masterbatch offers significant advantages

in terms of :

|

|

Accurate dosing |

|

|

Excellent Homogenization |

|

|

Absence of fine powder |

|

|

Absence of special legislation required for storage, etc. {Since

below 10% peroxide is not considered dangerous}

The converters can select one of the three products depending upon

requirements. However, the masterbatches possibilty offers the best

option. |

Previous Article

Next Article

Tell Us What You Want

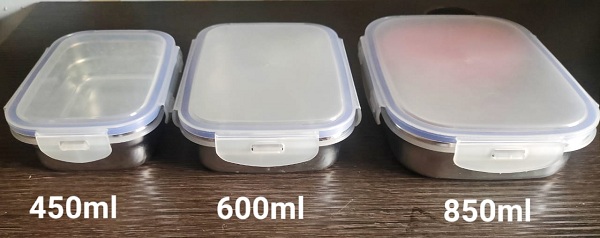

Unused tiffin, lunch box moulds

| | | |