|

Polymer blends are expected to grow well in the future as no new

polymers are being developed. Polymer blends are used when two different

polymers that may not be compatible with each other are required

to obtain a balance of properties. For instance, Polyolefins are

low cost polymers but do not have adequate barrier properties. They

are often blended with Polyamides to enhance the barrier properties.

Compatibilizers are those products that allow blending of two immiscible

polymers creating a homogeneous mixture. A compatibilzer works like

a surfactant, lowering the interfacial tension between two incompatible

polymers, thus allowing them to mix. The blends may continue to

have two different phases but behave as if they are miscible. The

compatibilizer usually has two parts so that each part can interact

with the respective polymer in the blend.

There are essentially two type of compatibilizers :

Reactive compatibilizers develop covalent

bonds while non-reactive compatiblizers are typically miscible with

one of the polymers from the blend. A compounder should select the

compatibilizer that matches the polymers in the blend. Reactive

compatibilizers require a reactive counter group while non-reactive

compatibilizers should have good miscibility as well as good viscosity

match.

Some of the common compatibilizers are:

|

|

Copolymers of Ethylene with either EthyleneAcrylic Acid,

ButylAcrylic Acid or MethylAcrylic Acid |

|

|

Ethylene-butylacrylate-glicidyl methacrylate |

|

|

Maleic Anhydride grafted Polyolefins or SBS Copolymers |

|

|

Copolymers of PMMA or PS with PP |

From the above compatibilizers, copolymers are non-reactive while

Maleic Anhydride grafted and Ethylene-butylacrylate-glicidyl methacrylate

are reactive compatibilizers.

Crompton, Dexco, Dow, Dupont and Kraton are the major players in

the business of compatibilizers. It is estimated that the global

market of compatibilizers would grow more than 5% from the level

of 15 KT to about 18KT by 2005. All compounders can take the advantage

of these compatibilizers to enhance the value of their compounds.

Previous Article

Next Article

Tell Us What You Want

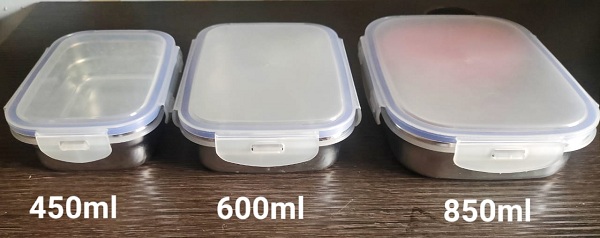

Unused tiffin, lunch box moulds

| | | |