|

OSS-SMC is a method for producing light weight parts, by employing

a sandwich structure of SMC in HOT press moulding. This SMC sandwich

component is nothing but SMC(Sheet Moulding Compound) with two layers,

the outer layer is SMC (based material) and the core layer is "foamed

SMC" (SMC+blowing agent).

The main advantage of this process is reduction in no. of steps

in production process (Hence the name "One step process").

Thus it is a cost savings method. Many of the vehicle parts that

the currently being made of conventional SMC, could soon be replaced

by OSS-SMC components.

The sandwich structure of SMC improves the rigidity of the product

compared to conventional SMC component. The comparison is by subjecting

the materials to area load. The different materials show clearly

the light weight construction potential of OSS-SMC. OSS-SMC is 34%

lighter than a conventional SMC and 56% lighter than steel.

Material Selection

Material Selection

The Material for outer layer is a standard low shrink SMC, which

was modified in such a way so as to fulfill the process requirements.

The core layer is based on a conventional SMC with a low glass flibre

content and at 30 to 40% by volume, contains high volume of SMC

recyclate. The sandwich component thus constitutes a mono system

which can be recycled without need for material segregation. An

alcohol is used as the blowing agent.

|

Production Production

Production

Process Production

Process

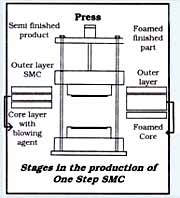

The figure shows the process sequence of the One step sandwich

SMC.

For producing SMC sandwich component, the process sequence

includes three phases – pre pressing, foaming and curing.

First, the SMC foamed core is formed by adding blowing agent

to the SMC. Then this multiplayer SMC blank is laid flat in

the compression mould in a HOT press moulding machine and

pre pressing is done. Once the mould has been filled, the

foaming process , necessary to give the desire sandwich thickness

takes place. The foaming pressure of the core material ensures

that the outer layer remains in contact with the mould surface.

After outer layer is cured, the mould is opened with simultaneous

foaming of core layer. Then the part is demoulded.The structure

of this moulded part corresponds to that of 'constructed sandwich

SMC' whose outer layers are made of conventional SMC. SMC

sandwich made by this process does not need to be completely

flat, but can be geometrically structured, for example with

spherical curvatures.

|

Conclusion

Conclusion

Earlier, the production of a sandwich component with classical

outer structure and core layer is not acceptable because of higher

production cost, due to more steps involved during production. But

this ,one step method reduces the number of steps involved, also

this method is suitable for producing 3D curved parts and the parts

can be recycled without the need to segregate the materials.

OSS-SMC can be preferred for vehicle utility parts such as roof,

door, floor and rear wall. Add on parts such as hinges, gas pressure

springs, lock catches and radiator grills can be attached directly

to the OSS-SMC. No support structure is needed.

Further development of this process is aimed at increasing the

performance of sandwich system in terms of its mechanics and surface

quality.

Previous Article

Next Article

Tell Us What You Want

Windmoller and Holscher 5 layer cast film line

| | | |