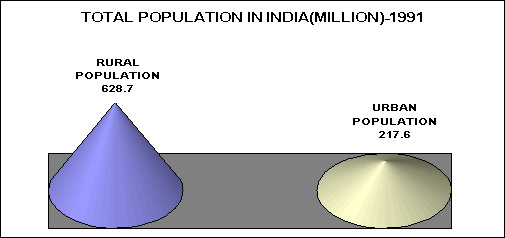

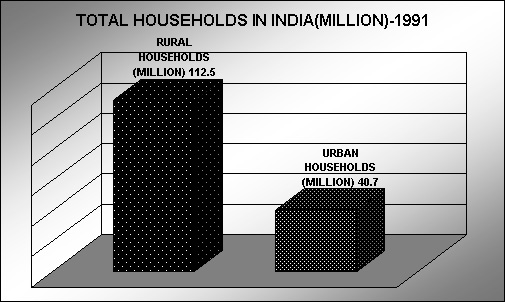

| New product as well as end use innovations would help manufacturers achieve a safety net for their business for a period of above 15-20 years. These new product and new end use innovations would help : * in increasing the selling price of the final product which would lead to an increase of average selling price of the final product bringing in a higher net profitability and lower payback periods in comparison to existing business. * help manufacturers manufacture products for new end uses without an investment on plant and machinery and also without much investment in marketing of the products, as well as to increase the product mix with an investment only in moulds and dies without any investment on plant and machinery and could manufacture products on the same plant and machinery. * help plastic rank as one of the top ranking material in agribusiness, building & construction, infrastructure and automotive enduse sectors helping plastic increase the per capita consumption from a single digit to triple digit in the country. One such end use of high density polyethylene pipes is that of use as homes for rural population which could increase the per capita consumption of plastics from a single digit to a triple digit. HDPE Pipes with outer diameter of 1 metre of 10 feet height could be laid into the ground in vertical direction � 3 nos pipes of 1 metre diameter in 3 horizontal rows of 3 i.e. 3 * 3 pipes of outer diameter 1 metre to make a square of 9. These pipes could be laid into the ground in vertical direction 3 feet below the ground so that during rainy season, these pipes would not get drowned. HDPE pipes could be laid 3 feet below the ground in vertical direction with only walls of HDPE pipes with the balance material of the pipes to be sawn from the centre which could be fed into the extruder and reused for manufacturing another home made out of 1 metre outer diameter HDPE pipes. Lids made out of injection moulding process could be fitted on the top of HDPE pipes which could be kept closed during winter and rainy season and kept open during summer. Small windows could be provided for winter and rainy season. 1000 mm Outer Diameter, Minimum wall thickness 25.8 mm, Weight per metre � 76.3 kg (Validation & Inputs from a Large Diameter HDPE Pipe Manufacturer in India) Costing Weight of 1 HDPE Pipe of 1000 mm Outer Diameter of wall thickness 25.8 mm & 10 feet length = 76.3 * 3 = 229 kgs * 0.15 (Assuming 15% of HDPE Pipes as wall of a home) = 34.35 kgs Weight of 9 HDPE Pipes of 1000 mm Outer Diameter of wall thickness 25.8 mm = 34.35*9 = 309 kgs = Rs 31,054 for 9 sqmts or 90 sqft Potential in India Assuming 70 crore population in rural areas(70% of total population) & assuming 5 persons per home in a home of 900 sqft = 14 crore homes of 900 sqft = 3090*140000000 = 432 kgs plastics per capita consumption in the country   (Source: Government of India � National Buildings Organisation, Ministry of Urban Affairs & Employment: Prominent Facts on Housing 1997) This New Enduse Innovation on HDPE Pipes would help increase the per capita consumption of plastics from a single digit to a triple digit. Source Courtsey : Poorvi C. Desai, Service to Plastic Industry

|

Previous Article

Next Article

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}