|

Paper is one of the highest consumed natural materials for commercial

as well as domestic use, for a large spectrum of applications. This

means that paper is the greatest culprit for problems of ecology

and enviornment, because most of the paper produced results in the

cutting down of forests.

With a view to preserve the forests, development of synthetic paper

has been on for almost four decades. A first major break-through

was production of thin gauge partially oriented HM-HDPE film, around

1966 in India. But it was not very close to natural paper in many

important properties.

The synthetic paper that is now developed and commerically gaining

a substantial penetration in the paper domain is based on HDPE and

PP by blown and cast processes, using a specially developed paper

masterbatch.

The paper master-batch for HDPE / PP is offered by Schulman and

represented by Reifenhauser Marketing in India.

The trials were taken on Kolsite 3-Layer blown film line and Colines

CPP Film line using HDPE and PP with the Masterbatch and the results

were encouraging. The results with HDPE on a Blown Film Line with

a little orientation were excellent.

Salient properties

Salient properties

|

|

Synthetic paper contains no fibres and is not coated. Therefore

it is ideal for those applications where contact with water and

moisture is likely. |

|

|

The paper is tough, with outstanding tear resistance, folding strength,

tensile strength and shock resistance. |

|

|

This paper has excellent resistance to chemicals. |

|

|

It has outstanding smoothness, which ensures high print quality

and the finest finish by coating and lamination. |

|

|

It is absolutely safe for the environment and is fully recycleable. |

|

|

The paper thus produced has all the properties very close to that

of natural paper - it can be printed by all the known methods,

can be written on by ball pen, computer printouts with dotmatrix as

well as laser printers are possible. It can be folded,

creased, and also stuck with an adhesive. |

|

|

It is very ideally suited as a packing paper for applications such

as laminated soap wrappers, twist-wrap as well with great

advantage for advertisement billboards, machine catalogues, annual

reports, documents required to be preserved, calendars,

tourist maps, cards for educational equipments, book covers, book

pages, etc. |

|

|

One great advantage is that it can be recycled like any plastics

film. |

|

|

The synthetic paper has dimensional stability, waterproofness, resistance

to chemicals, smoothness, whiteness and can be washed

clean. These properties have replaced the synthetic paper instead

of paper in applications such as copy papers, second

originals, thermal papers for clean room, bar code labels and video

printer, computer forms, drawing papers,plotter

papers, etc. |

|

|

The market is importing its requirements mainly from Japan, but

no special efforts have been made to develop themarket. |

Printing

Printing

The paper can be printed on a regular offset printing machine commonly

used for printing paper. For best results, the top and bottom sheet

that have been kept in contact with the cardboard packing sheet of

each pack, should be discarded. The paper should be brought into the

printing room at least a day before printing, in order to condition

it to the room temperature and prevent moisture condensation. The

relative humidity at the machine should be maintained at not less

than 50% to minimize electrostatic problem.

Printing conditions

Printing conditions

|

|

Feeder

Unwrapped sheets should be fanned before stacking to ensure smooth

feeding. Folding is prohibited. The stacking should not be loaded

with more than 5,000 sheets at a time. |

|

|

Abrasions and Marks

To avoid sucker marks, minimize the suction pressure and/or

cover the rubber part of the sucker with cloth tape to avoid wheels

and brushes marks, move them away from the image area or cover them

with either PP tape or cloth tape. |

|

|

Plates

Pre-sensitized (PS) Plates are the most recommended. |

|

|

Press setting

Printing pressure should be maintained as high as possible.

The blanket will sometimes show whitening which comes from the inorganic

fillers and normally has no effect on print quality. |

|

|

Dampening water

As the paper is not absorbent, it is important to keep the amount

of the dampening water to a minimum, so as to avoid poor ink adhesion,

longer drying times, set-off and washed out printed images. |

Packing

Packing

Spray powder should be used and it should be of the hydrophilic

type (i.e. having an affinity for water, but not soluble). Soluble

or water-repellent powders are not suitable.

It is suggested that:

|

|

sheets should be stacked in piles of 500-1000. |

|

|

air-pressure and jogging should be reduced to a minimum. |

|

|

sheets should not be subjected to impacts or shocks. |

|

|

humidity at delivery should be kept over 50% at least to avoid

static problem. |

Drying

Drying

This paper is not absorbent, and therefore, drying will take longer

than with paper. Typical drying time :

1 colour 4-6 hours, 2 colour 5-8 hours, 4 colour 6-10 hours.

Inks

Inks

Inks must be specially formulated for synthetic papers and consist

of 100% solids, contain less than 3% mineral oil and dry by oxidation.

Applications

Applications

Some of the very common applications in Japan as per one of the

very large manufacturers like YUPO (Japan) include the following:-

|

|

General graphics: Outdoor posters, sign boards, catalogues,

pamphlets, calendars and menus. |

|

|

Publication: Book pages, children books and maps. |

|

|

Packaging: Mould-in labels, overwraps, blister packs,

labels of all kinds including self-adhesive labels. |

|

|

Bags: Shopping bags, envelopes, courier bags, x-ray envelopes

and preservation bags. |

|

|

Special applications: Ballot papers, golf score cards,

ski tickets, various manuals, business cards and battery insulation

paper. |

The market potential appears extremely good, particularly because

it can be produced on Indian equipments, with Indian Polymers and

with comparatively small investments.

For more details, contact plastemart.com

Previous Article

Next Article

Tell Us What You Want

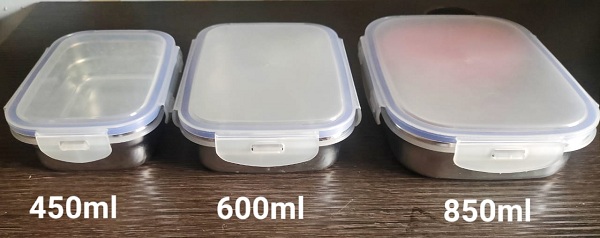

Unused tiffin, lunch box moulds

| | | |