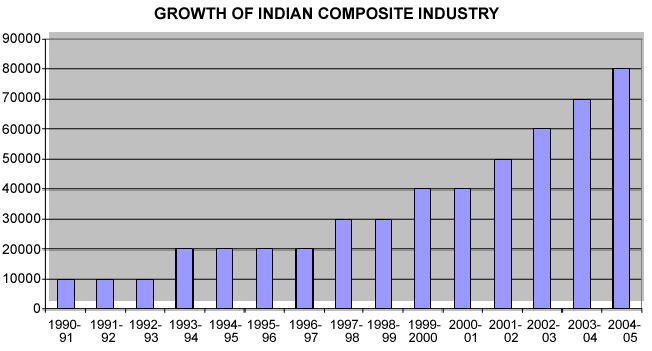

In the last few years of the previous decade, the high cost of raw materials, lack of availability of many essential materials because of import restrictions and the lack of mechanized production methods, affected the large scale production of composites in India. As a result, Indian composite industry could not compete with steel, aluminum or timber. In the last three decades, more than 1200 small-scale industries have been established in the country. Over 98% of them use hand lay-up technique for composite fabrication. Improvements in volume growth only started in early 2000 as a result of the globalization of the Indian economy. The total production of composite was about 75,000 tons in 2004-05, and 1,10,000 tons in 2005-06. The following graph shows the growth of Indian composite industry from 1990 onwards :  India has made tremendous progress in wind power sector propelling composite consumption to exceed China and Japan. India is the fourth largest generator of wind power in the world. As per estimates, approximately 100,000 MW of power can be produced in India from only small wind turbines of 10 to 500 KW capacities. The major use of composite in India began with chemical industry because of excellent corrosion resistance property of composites. Some of the applications include chemical equipment, piping, cooling tower, fire fighting breathing apparatus etc. Composite pipes find applications in sea-water intake and effluent discharge in desalination plant, as ducts in chemical industry, cross country transmission water pipeline, sewerages pipelines etc. Composites are being used for fabricating cooling tower units to resist corrosion due to moisture. The present consumption of composite along with future growth potential in the aforesaid sector is mentioned below:

The composites was identified as a potential material for its application in the Indian Railways in early 80s for many passenger coach components such as louvre & glass shutters, window sill & frame, trays for battery boxes, roof ceiling, flooring etc. The railways were aiming towards complete elimination of timber & plywood usage in the coaches. The present consumption of composite materials has been estimated at about 8,000 tons in Indian Railways with annual growth rate of 20%. The automobile industry is another sector wherein significant composite materials have been used significantly in passenger car, scooter and helmet. The growth rate of composites in the automobile sector has been as follows :

There exist the vast potential of composite applications in high-pressure pipes & pipe fittings in coming years in the oil & gas sector. Current offshore structural applications of composites include low-pressure pipe, gratings, handrails, equipment covers or enclosures and ladders. Because of lightweight, corrosion resistance, improved life-cycle costs and enhanced safety, composite can capture 50% of this market in the oil & gas sector in the next 5-6 years. The use of composites for boat building applications started in early 1970s for replacing wood because of certain advantages such as corrosion resistance, ease of fabrication, improved performance and low cost. The marine market for composites stood around 1000 tpa as on 2006 and this is expected to grow at 3000 tons by 2010, with applications in leisure boats, houseboats, speedboats etc. The present overall consumption of composites has been estimated at around 110,000 tpa as summarized below: All figures in �000 tons

Indian composites market has been growing rapidly with newer products manufactured with the gradual induction of modern technology. The analysis of India's composite market reveals that although many small fabricators are using hand lay-up methods for manufacturing composite products, the use of computer controlled advanced fabrication equipment such as filament winding system, pultrusion, RTM and other equipment is growing rapidly. There is a huge potential for use of composite in Indian automobile industry especially for catering to the transportation needs of growing middle class population. There would be a good market for hoods, cabs, frames, and cargo containers that could be used as part of these locally built vehicles. The business opportunities for Indian composites industry also include air intake manifold, composite fishing trawlers, refrigerated freight containers, pressure vessel for gas, motor driven carts, storage light houses, boats for Tuna fishing, thermoformed components for automotive applications, walkways & piles for building foundation, RCC casting shutters leaf spring, air intake manifold etc. (Source: TIFAC study) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Previous Article

Next Article

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}