|

Indian Plastics Institute (IPI) organized a

two day conference on Styrenics at Mumbai recently.

This was probably the first time that a conference

devoted entirely to Styrenics was held in the

Asian region.

Styrenics products, although quite old, have

not kept pace with Polyolefins as well as Vinyls

due to the inherent higher costs of feedstocks.

In fact, Styrenics constituted only 21 million

tons of the total global plastics consumption

of 165 million tons in 2004. Indian Styrenic

consumption was less than 300KT in 2003 and

lagged behind when compared to Polyolefins and

Vinyls.

This conference brought about the confirmation

of the news that Reliance Industries is setting

up a 550KT capacity Styrene Monomer plant at

Jamnagar using the Ethyl Benzene process of

ABB Lummus/UOP, likely to be commissioned by

the end of 2006.

Highlights of the conference:

|

|

Alpha Methyl

Styrene dimer was shown to produce narrower

molecular weight distribution in Polystyrene

compared to the other chain terminating

agents. |

|

|

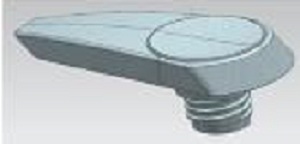

Mounting is simple for different

moulds |

|

|

Reduced clamping forces |

|

|

Subsequent assembly is eliminated |

The major usage of Styrenics is in the fields

of automobile (ABS), white goods (HIPS/ABS),

electronics (PS/HIPS). Disposable rigid packaging

is possibly the application that constitutes

40% of the global Styrenic consumption. However

only 10% of Styrenics consumed in India finds

usage in packaging. Another interesting application

of foamed Polystyrene is in the area of construction

where it provides excellent insulation. Expandable

Polystyrene as well as extruded foams are used

in this application with each providing some

advantages compared to the other. Both routes

are widely used.

While General Purpose Polystyrene and High

Impact Polystyrene as well as ABS have a major

share of 21 million tons consumption, other

specialty products such as SBS/SIS/SEBS/SEPS

as elastomeric polymers and ASA, MABS and blends

of PC/ABS, PPO/PS also have a very interesting

applications. These specialities are expected

to have about 10-15% share of the total market

of Styrenics.

With 3 large producers of Polystyrene and 2

producers of ABS, India is self-sufficient and

can provide the current needs of the Indian

industry. In fact, almost 100KT of Polystyrene

is exported from India. This situation will

continue for at least another 3-5 years. It

is expected that with the local availability

of Styrene monomer in 2007, the Indian market

would show better growth.

Previous Article

Next Article

Tell Us What You Want

Moulds for lotion pump

| | | |