|

|

|

|

|

An Overview of Pakistan's Plastics Industry An Overview of Pakistan's Plastics Industry |

|

|

|

| |

|

Plastics industry in Pakistan is one of the oldest in the

country and its existence can be traced out even

in the year 1947 when Pakistan came into being.

Obviously, at that time, the industry was ill-organised

and progressed in a haphazard manner producing

low quality toys and household utensils on hand

molding machines. Whatever the quantity of those

machines was, they were small in number and all

set in Lahore, an important commercial centre

of Punjab till date. The period from 1965-1975

was notably the turning point, where the use of

plastics was seen rising to a leading force in

the country, with a sizeable base.

The plastics industry in Pakistan has taken great

strides in quest for its success. Today plastics

material constitutes as the fourth largest item

of imports and this sector alone contributes significantly

to the national exchequer in different heads.

The industry is growing at an annual average of

15% and in the process of development it has surpassed

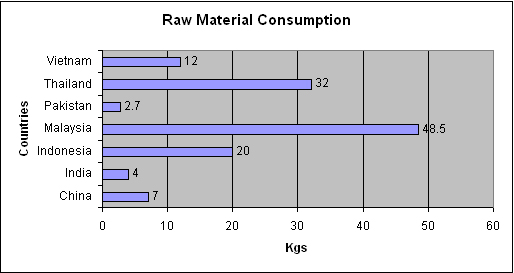

all other industrial sectors. The per capita consumption

in the country has also shown an upward trend

during the last 15 years [except post 9/11 events

and standoff with India]. Today the domestic consumption

of plastics stands at 2.7 kgs, far less than the

international average, yet Pakistan is the second

largest domestic market in South East Asia after

India. With the 175 million strong population

of Pakistan growing at an annual rate of 2.2%,

coupled with new foreign and local investment

and the government policy advocating use of PP

woven bags for industrial packaging, it is expected

that the per capita consumption of plastics is

like to increase to 4.0 kgs by 2007. Till the

early years of 1990s, the customs duty on plastics

raw material was on unrealistically higher side

of about 110 % which has been gradually brought

down to the current level of 20%.

|

|

There is a tremendous scope for expansion in the

plastics sector. As mentioned above the per capita

consumption of plastics as compared with the neighboring

and other regional countries, is still low, but

again this low consumption level indicates that

there is a lot of potential for this industry. For

instance, the usage of plastics in auto industry

has reversed the consumption trend. With due attention

to enhance the productivity and improving quality

through innovative technique, the exports of plastics

auto parts, which was virtually unheard of in recent

years, has become an export industry in Pakistan.

Undeniably, had it not been for the import of

second hand machinery and cheap labour, the plastics

industry in Pakistan would have long vanished.

Ironically, the second biggest factor that hampered

the development of local plastics industry was

a ban on import of brand new plastic machines.

The government imposed the ban on plastics machinery

for the reason that all of the raw material used

for manufacturing of plastics goods was imported

and the machinery may be misused. After long year,

the plastics manufacturers succeeded in convincing

the government that the plastics machines can

manufacture plastics goods and nothing else, and

hence the possibility of their being misused for

purpose other than the plastics manufacturing

is minimal. Other reason for the slow growth of

this industry was the NRI (Non Refundable Item)

policy (imposed by the government) on plastics

machinery, at a time when no injection molding

plastics machine was being produce domestically.

The ban on new plastics machines was lifted in

1984, but very few new machines of modern technology

made their way into Pakistan by way of imports

during the next 10 years. However, since then,

the industry has taken giant steps in bringing

the quality of local products at par with the

international standards.

|

|

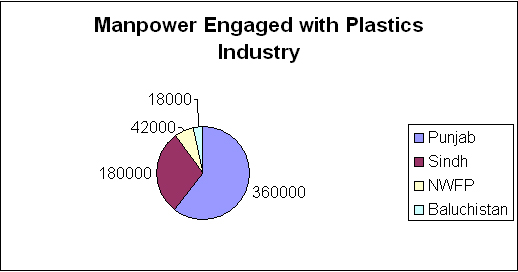

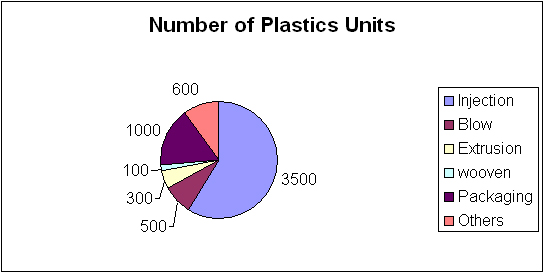

Presently there are 6000 plastics

processors in Pakistan. The entire industry is self-financed

and SME. The industry contributes around Rupees

8 billion annually to the national exchequer by

way of custom duty, sales tax and income tax. Major

concentration of plastics processors whether they

are injection, blow, extrusion, woven or tubular

films manufacturers, is in and around the industrial

hubs of Karachi, Lahore, Gujranwala, Peshawar, Faisalabad,

Hyderabad , Rawalpindi, Gadoon and Hattar.

|

|

The industry can be divided into two sector i.e

organized and unorganized. Organized sector, with

about 600-650 units, is capable of producing quality

about 600-700 units, is capable of producing quality

products. The unorganized sector produces low quality

and cheap products. Despite this, the unorganized

sector has grown faster than the organized sector

in the past15 years.

|

|

Currently there are four plants in Pakistan producing

international quality plastics raw material. Surplus

production of these plants in being exported. All

of them are located within the limits of Karachi.

Concept of international plastics exhibitions

in Pakistan is relatively new. The first plastics

exhibition was held last year May. With more exhibitors

coming to Pakistan in a second plastics exhibition

within a year, the plastics industry in Pakistan

surely has a lot to show and gain from the international

plastics players. |

Vital Signs |

| Major Raw Material Producers (operating) |

4 |

| Processing Units |

6,000 |

| Employment Direct / Indirect |

470,000 |

| Investments (domestic) |

Rs. 23.671 Bn |

| Investment (foreign) |

Investment (foreign) |

49% |

| Capacity Utilization |

95.4% |

| Raw Material Produced (approx) |

253,000 (metric tons) |

| Raw Material Consumed |

450,000 (metric tons) |

| Export value (approx) |

Rs.56,369,000 |

| Export Growth |

35% average |

| Revenue to Government (approx) |

Rs.800 crores (Rs.8 bln) |

| Contribution to Total Exports |

0.277% |

Demand Estimates For Machinery

| Injection Molding |

250-500 |

| Blow Molding |

350-500 |

| Extrusion |

1000 |

Please

click here to express your feedback/queries

(Contributed by Fayyaz A. Chaudhry-

Secretary of Pakistan Plastics Manufacturers Association)

Previous Article

Next Article

Tell Us What You Want

Dispenser Pump, Spray Pump

| | | | | | | | |