|

Inspired by carbon-capturing processes found in nature, a new technology has been developed, patented and commercialized - a carbon capture technology that extracts carbon molecules from air containing greenhouse gas and re-arranges those molecules into long-chain thermoplastic polymers that can match the performance of oil-based plastics and out-compete oil-based plastics on price. Newlight Technologies’ has been continuously operating its technology at large scale over a number of years on a variety of gas sources, ranging from methane-based biogas to CO2-rich air. Newlight’s conversion technology can synthesize high-performance thermoplastics from a wide range of sources, including from wastewater treatment facilities, landfills, digesters, or energy facilities. Newlight GHG-to-Plastic™ Process |

| Capture: First, air and greenhouse gas (such as methane/carbon dioxide biogas) is directed into Newlight's patented conversion reactor. |

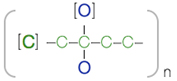

| Isolate: Second, carbon and oxygen are removed from the air-GHG stream and isolated for polymerization. |

| Polymerize: Finally, isolated carbon and oxygen are re-assembled into a long-chain thermopolymer. |

|

Newlight Technologies, LLC has been awarded a seventh patent related to the conversion of greenhouse gases, such as waste methane and carbon dioxide, into biodegradable PHA plastics. The new patent joins the company's multi-layered and continually-expanding portfolio of intellectual property, which now includes seven U.S. and international patents and hundreds of additional filed patent claims. The company was founded in 2003 out of Princeton University and Northwestern University to convert greenhouse gas emissions into commercially useful materials. With almost a decade of multi-scale operations converting greenhouse gases into high-performance biodegradable plastics, Newlight has developed a deep and multi-layered patent portfolio covering the company's gas-to-plastic operations, including patented and patent-pending claims on: |

|

Previous Article

Next Article

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}